Oven achieves accurate temperature control and keeps its biscuit safe

Let's put aside the hazelnut oatmeal biscuits market is still not sold, let's first understand what is the harm of acrylamide? Why do biscuits contain acrylamide? How should biscuit processing enterprises avoid the production of acrylamide in biscuits?

Generally speaking, starch-based foods are very easy to produce acrylamide under high temperature (more than 120 ℃) cooking. Starch foods such as common frying and grilling have been detected as a carcinogen due to frying and grilling under high temperature conditions, so acrylamide has been detected. It is understood that in the list of carcinogens published by the World Health Organization International Agency for Research on Cancer, acrylamide is in the list of category 2 carcinogens. If the human body is exposed to acrylamide through the digestive tract and respiratory tract for a long time, it will have a certain neurotoxic effect on the human body.

Industry sources said that the formation of acrylamide is related to the way of processing and cooking, temperature, time, moisture and so on. Many foods are susceptible to acrylamide when cooked at high temperatures, such as baked biscuits, fried foods, and grilled foods. At present, there are no clear regulations on the dosage of acrylamide in relevant Chinese standards. In the world, only the EU limits the content of acrylamide in foods, of which biscuits and cookies are 350 ug / kg. Although the national standard does not strictly limit acrylamide, it is true that eating food containing the substance for a long time is harmful to the human body.

So, how to reduce the production of acrylamide and avoid excessive intake? On the one hand, you should try to avoid over-cooking food, so that the temperature is not too high or the heating time is too long. On the other hand, biscuit food processing enterprises should improve the food processing technology and conditions, use professional baking equipment, and strictly control the baking temperature and time. At the same time, other possible ways to reduce the acrylamide in food are also studied, which is also conducive to optimizing the cooking conditions in the production of baked food in our country and the production and processing of household foods to avoid excessive production of acrylamide.

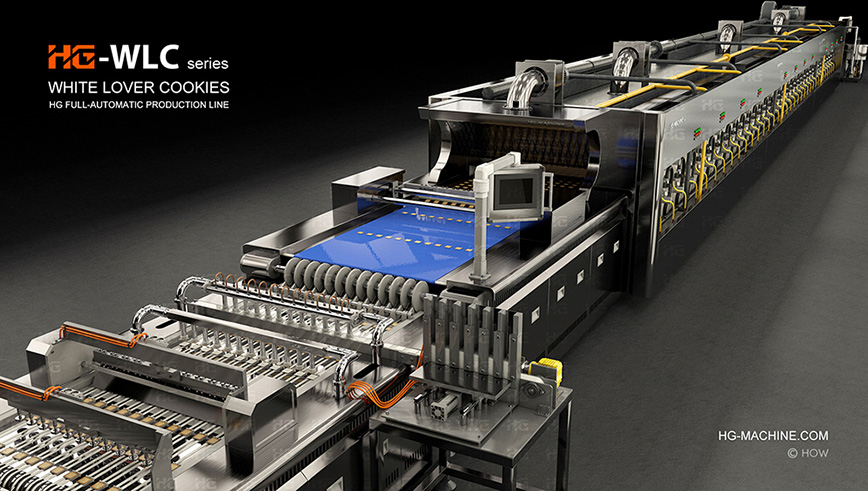

It is well known that the production of biscuit baked goods generally includes multiple processes such as dough, forming, baking, oil spraying, cooling, packaging and so on. In fact, as mentioned above, foods with high heating temperature and long time are prone to excessive production of acrylamide. Therefore, the control of dry baking time and temperature plays a vital role in avoiding the production of acrylamide.

At present, most of the biscuits ovens on the market use a temperature control system. The user can set the baking temperature and time in the processing process to avoid excessive temperature and long time, which will cause excessive production of acrylamide and ensure the safety of biscuits. In addition, the automatic control system in the box keeps the temperature constant, which can ensure the uniform heating of the biscuits in the box, avoid uneven heating, and affect the overall color and taste of the biscuits.

In addition, the use of forced air circulation heating with blast type not only improves the baking efficiency of biscuits, shortens the heating time, but also prevents acrylamide from being produced due to the long baking time of biscuits to ensure the quality of biscuits. . In addition, because the biscuits heat fast, the baking time is short, the thermal efficiency is high, and the energy consumption is low, which saves energy costs for the enterprise.

Needless to say, long-term consumption of foods containing acrylamide is more harmful to the human body. To this end, food processing enterprises must establish a strong sense of social responsibility, by continuously improving the food processing technology, using professional baking equipment, such as baking ovens, control the heating temperature and time, to avoid excessive production of acrylamide, to a certain extent To ensure the safety of biscuits, let consumers eat with confidence.

Shanghai HG Food Machinery Co.,ltd is food machinery and equipment supplier, specializes at making cookies

English

English