Industry Knowledge

Choco Pie and Sandwich Cake Production Line Overview

A choco pie production line, also known as a sandwich cake production line, is designed for the continuous manufacturing of filled and sandwiched cake products. Using eggs and flour as primary raw materials, the line produces chocolate pies, strawberry pies, and similar snack cakes through a fully automated process that supports consistent structure, taste, and appearance.

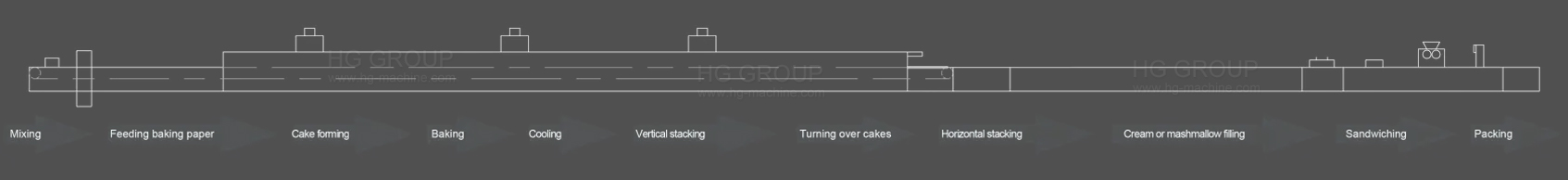

Complete Processing Flow for Sandwich Cakes

The fully automatic sandwich cake production line integrates multiple processing stages into a synchronized workflow, reducing manual handling and improving production efficiency.

- Slurry mixing and depositing to form uniform cake batter portions

- Tunnel oven baking followed by controlled cooling

- Vertical stacking, cake turning, and horizontal stacking for accurate alignment

- Cream filling and sandwiching to form finished choco pie structures

- Final cooling and packing to support stable shelf life

Main Equipment Configuration

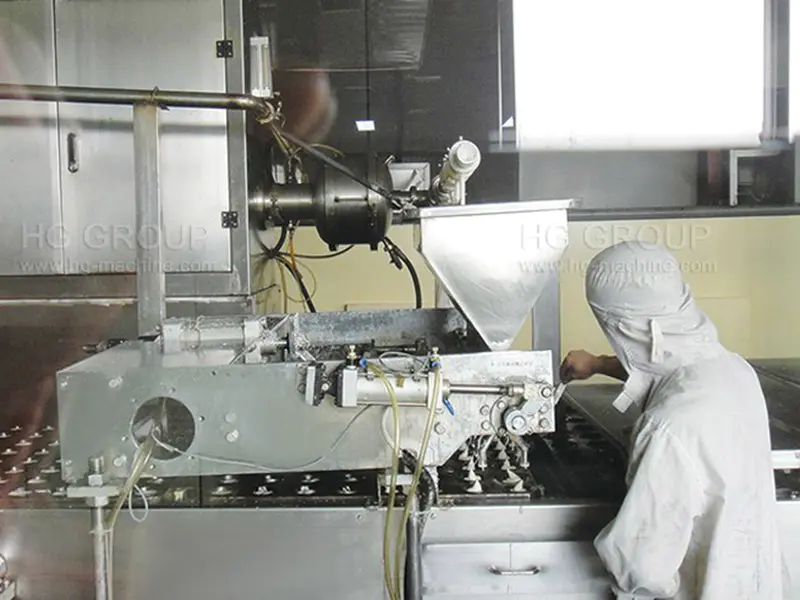

A standard choco pie production line consists of a slurry mixer, paper feeder, depositing and forming machine, tunnel oven, cooling conveyor, paper recycling unit, stacking machines, cake turnover machine, sandwiching machine for cream filling, and cooling equipment. For extended product varieties, a chocolate coating machine can be added to produce coated chocolate pies.

Automation Advantages in Industrial Production

With a high level of automation, sandwich cake production lines operate with stable performance and high output efficiency. Automated stacking, turning, and filling reduce labor dependence while improving product uniformity, making the line suitable for long-term continuous production.

Technology Development and R&D Support

HG Industry Group continues to invest in food machinery research and development, introducing advanced design concepts and processing standards from Japan, Europe, and North America. These technologies are further optimized through localized engineering to match real production environments.

Its R&D team, composed of mechanical engineers, food technologists, and automation specialists, verifies and refines each process and equipment configuration, supporting customized choco pie and sandwich cake production line solutions for different market needs.

English

English

Non-contact conveying

Non-contact conveying  Precise stacking of double-layer cakes

Precise stacking of double-layer cakes  Energy-saving thermal cycle design

Energy-saving thermal cycle design