Industry Knowledge

HG Industry Group's Compound Potato Chips Production Line: Versatility and Efficiency

HG Industry Group, with its legacy of 50 years in food machinery, continues to set industry standards with innovative solutions in snack production. Established in 1975, HG Food Machinery has grown into a leading manufacturer of specialized production lines, including the advanced Compound Potato Chips Production Line. With a global presence in over 100 countries and assets exceeding RMB 2 billion, HG has leveraged its extensive expertise to cater to the evolving demands of the snack industry.

The Compound Potato Chips Production Line by HG Food Machinery is designed to meet the growing demand for high-quality, multi-layered potato chips with a wide range of textures and flavors. Whether you are looking to produce a crispy snack or a more complex, multi-flavored potato chip, HG's equipment offers the flexibility and efficiency needed for consistent production.

Key Features of HG Compound Potato Chips Production Line

- Multi-layer production: The compound production line allows for the creation of layered chips, enhancing the flavor and texture by incorporating multiple ingredients.

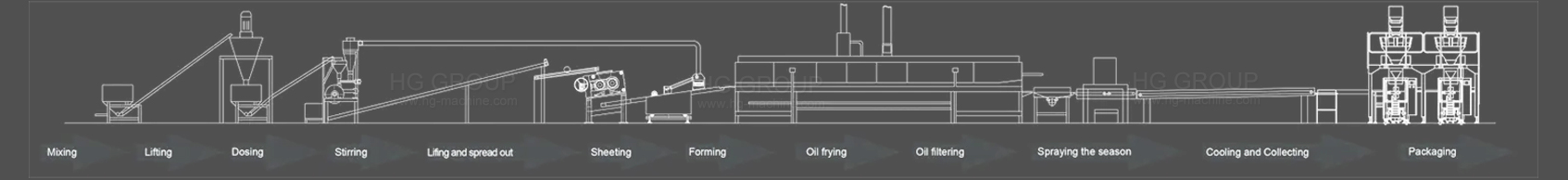

- Automated processes: From raw material preparation to final packaging, HG’s production lines provide full automation, ensuring a smooth and efficient operation with minimal human intervention.

- Energy-saving technology: The equipment is designed to reduce energy consumption while maximizing throughput, making it cost-effective and environmentally friendly.

- Customizable configurations: The line can be customized based on the desired product characteristics, such as chip size, flavor layering, and texture, offering high versatility for snack manufacturers.

- Consistency and precision: The machinery is designed to produce uniform layers of chips, ensuring consistent texture and taste across every batch.

Applications of Compound Potato Chips Production Line

The Compound Potato Chips Production Line is ideal for manufacturers looking to diversify their product offerings. Some of the most common applications include:

- Multi-layer potato chips with different textures

- Flavored compound chips, including cheese, sour cream, and spicy variations

- Health-conscious chips with reduced fat or alternative seasonings

- Premium or gourmet chips with unique ingredients or seasonings

Efficiency and Innovation in Compound Potato Chips Production

HG Food Machinery’s Compound Potato Chips Production Line is built with advanced technology to streamline production while maintaining high quality. By incorporating cutting-edge automation, the line reduces human error, minimizes production downtime, and increases overall throughput. This level of innovation helps manufacturers meet increasing demands for compound snack products, all while maintaining consistency in flavor and texture.

One of the standout features of this production line is the precision with which it layers potato chips. This enables the creation of products with a variety of textures and flavors, offering a unique edge in the competitive snack market. From the initial slicing to the final frying and packaging, the compound production line maintains a consistent product output, ensuring the highest quality with every batch.

Maintenance and Support for HG Compound Potato Chips Line

Maintaining the performance and longevity of the Compound Potato Chips Production Line is crucial for manufacturers looking to maximize their investment. HG Food Machinery offers comprehensive maintenance and support services that include:

- Preventive maintenance schedules to keep the production line in top condition and avoid unexpected breakdowns.

- Access to spare parts and components to reduce downtime in case of repairs.

- On-site and remote troubleshooting services to quickly address any operational issues.

- Operator and maintenance staff training to ensure safe and effective use of the machinery.

HG Industry Group's Global Expertise in Snack Production

With its extensive network of seven machinery branches, two food labs, and a research-driven industrial university, HG Food Machinery is well-positioned to provide cutting-edge solutions to snack manufacturers worldwide. The company’s robust infrastructure allows it to offer both localized and global support, ensuring that customers receive personalized service tailored to their specific needs.

HG’s Compound Potato Chips Production Line is part of its broader commitment to innovation in the food machinery sector. With a legacy of 50 years in the industry, HG continues to provide manufacturers with advanced production lines that not only meet the increasing demand for quality snack products but also help improve operational efficiency and sustainability.

English

English