Industry Knowledge

Understanding the White Lover Biscuit Production Line

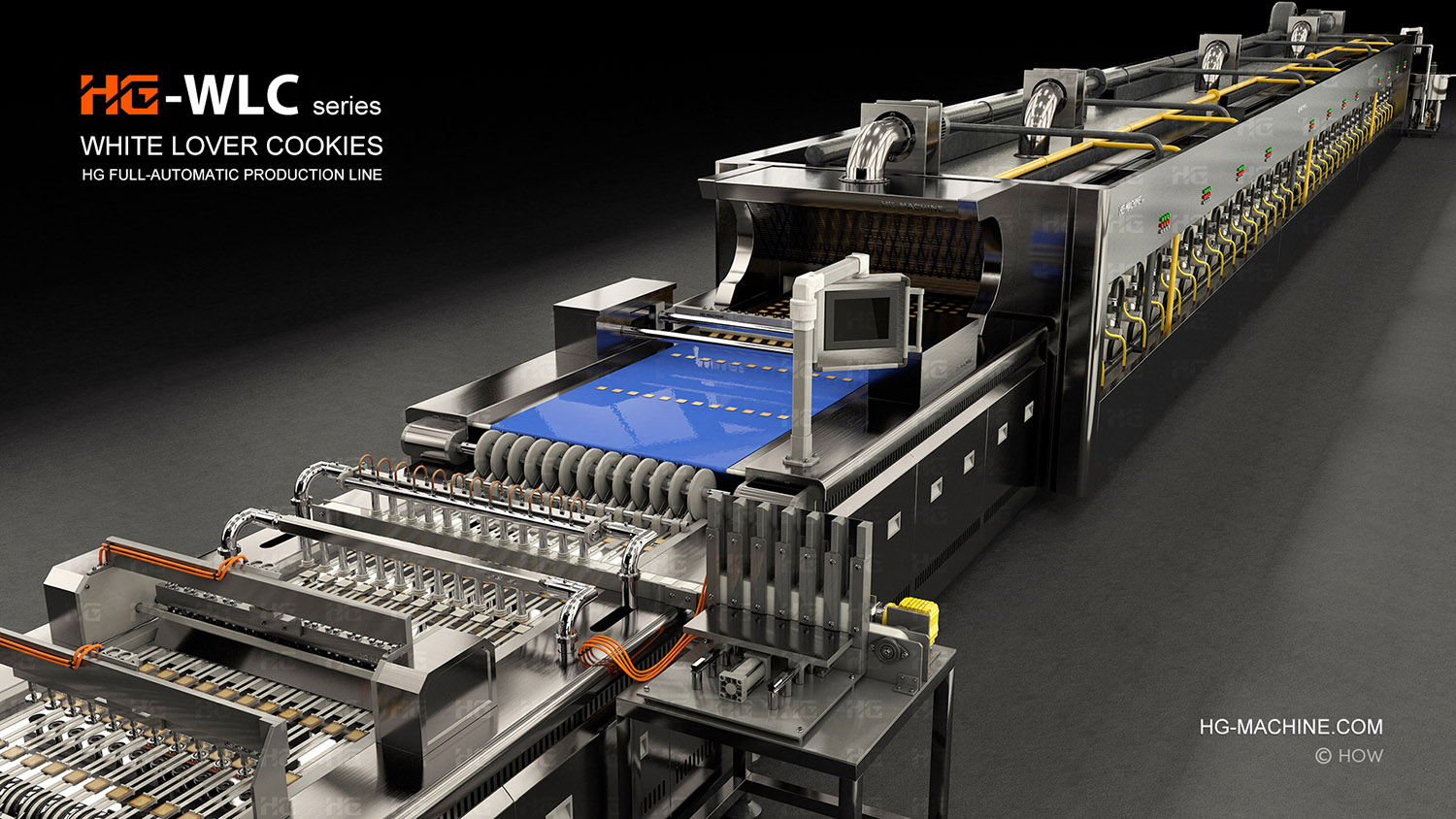

The White Lover production line is designed for the large-scale, stable manufacturing of high-end filled biscuits characterized by thin, crisp wafers and smooth cream layers. This type of product places extremely high demands on dough handling precision, baking uniformity, cream formulation, and sandwich accuracy. A mature production line must ensure consistent taste, appearance, and hygiene standards while maintaining high output efficiency.

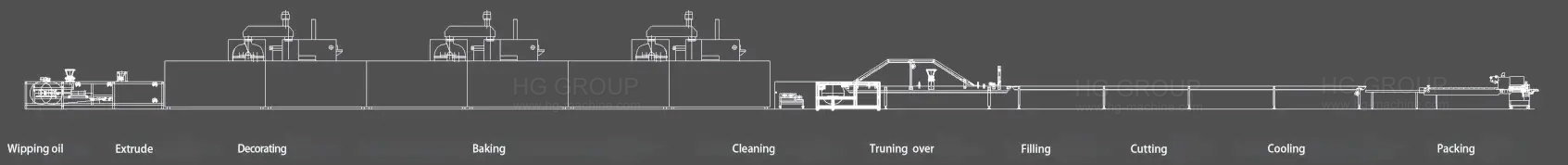

Core Process Flow of a White Lover Production Line

A complete White Lover production line integrates multiple synchronized systems, each optimized to protect wafer texture and cream quality. The process emphasizes gentle handling, precise temperature control, and continuous automation.

- Batter mixing system ensuring uniform viscosity and stable aeration

- Wafer forming and depositing system with accurate weight and shape control

- Multi-zone tunnel oven for even baking and moisture control

- Wafer cooling and buffering section to prevent deformation

- Cream preparation, spreading, and sandwiching system

- Cutting, alignment, and automatic packaging integration

Key Technical Challenges and Solutions

White Lover biscuits are sensitive to temperature, humidity, and mechanical stress. An advanced production line addresses these challenges through intelligent design and precise control.

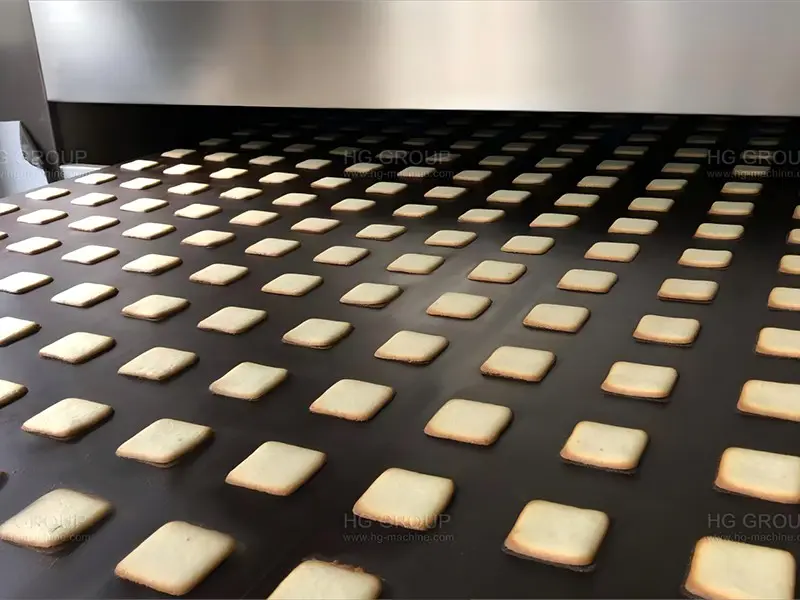

Wafer Flatness and Crispness Control

Uniform wafer thickness and moisture content are achieved through precision baking zones and controlled cooling conveyors. Stable airflow and temperature profiles prevent warping and cracking, which are common issues in high-speed wafer lines.

Cream Consistency and Hygienic Handling

The cream system must maintain smooth texture without oil separation. Food-grade stainless steel tanks, closed-loop pipelines, and temperature-controlled spreaders ensure consistent flavor while meeting international food safety standards.

Typical Configuration Parameters

| Production Capacity | 300–1,200 kg/hour |

| Oven Length | 30–90 meters (customizable) |

| Cream Types | Milk, Chocolate, Cheese, Flavored Cream |

| Automation Level | Semi-automatic to Fully Automatic |

HG Industry’s Expertise in White Lover Production Lines

With over 50 years of experience in food machinery manufacturing, HG Industry Group provides mature and reliable White Lover production line solutions. Its core manufacturing arm, HG Food Machinery, established in 1975, has evolved into a global supplier serving more than 100 countries.

HG Industry (Japan) functions as the group’s R&D center and led the breakthrough development of Japan’s renowned “White Lover” product. This hands-on product development experience allows HG to translate real production challenges into practical equipment solutions.

Supported by MWM (Shanghai), HG Industry delivers one-stop services covering raw materials, additives, complete factory equipment, and turnkey project execution. This integrated model ensures that customers receive not just machines, but stable, market-proven production systems.

Why a Turnkey White Lover Line Matters

For manufacturers entering or expanding in the premium wafer biscuit segment, a turnkey White Lover production line reduces trial costs, shortens commissioning time, and improves product consistency. Equipment matching, process optimization, and technical training are critical to achieving long-term operational stability.

HG Industry’s production lines are widely adopted by leading food brands across Asia, the Americas, Europe, and the Middle East, backed by strong technical support, international certifications, and continuous innovation.

English

English

Precise control of chocolate tempering

Precise control of chocolate tempering  Accurate fitting of cat's tongue biscuits

Accurate fitting of cat's tongue biscuits  Rapid cooling and setting

Rapid cooling and setting