Industry Knowledge

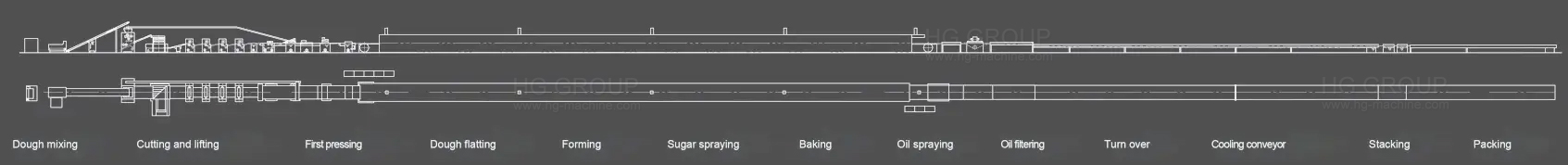

Soft Biscuit Production Line and Hard Biscuit Production Line Overview

Soft biscuit production line and hard biscuit production lines are core systems in modern biscuit manufacturing, each designed to meet distinct product textures, formulations, and market demands. Choosing the right line configuration directly affects product quality, production efficiency, energy consumption, and long-term operating costs. This article focuses on practical production differences, equipment structure, and how integrated solutions improve commercial biscuit manufacturing.

Key Differences Between Soft and Hard Biscuit Processing

Although both product types use similar raw materials such as flour, sugar, fats, and additives, the processing logic differs significantly. Dough rheology, forming methods, and baking profiles determine whether a line produces soft or hard biscuits.

- Soft biscuits rely on higher moisture dough, gentle mixing, and wire-cut or rotary molding.

- Hard biscuits require low-moisture dough, strong gluten development, and precise sheeting and lamination.

- Baking curves differ greatly, with soft biscuits focusing on surface structure and hard biscuits emphasizing internal crispness.

Soft Biscuit Production Line Structure and Functions

A soft biscuit production line is engineered for flexible dough handling and delicate shaping. The system prioritizes moisture retention, uniform portioning, and surface definition to achieve a tender texture and consistent appearance.

Dough Mixing and Feeding

Soft biscuit dough is mixed using planetary or horizontal mixers designed to minimize gluten overdevelopment. Precise temperature control ensures dough stability before forming.

Forming and Depositing

Wire-cut machines and rotary molders dominate soft biscuit forming. These systems allow rapid product changeover and accurate weight control, making them ideal for cookies, filled biscuits, and premium shortbread products.

Baking and Cooling

Multi-zone tunnel ovens with adjustable airflow and humidity settings are critical. Controlled cooling conveyors prevent deformation and preserve soft textures before packaging.

Hard Biscuit Production Line Structure and Functions

Hard biscuit production lines are designed for continuous, high-speed output and structural precision. The equipment focuses on dough strength, sheet uniformity, and moisture reduction.

Dough Development and Resting

Hard biscuit dough undergoes intensive mixing followed by controlled resting to develop gluten. This process is essential for producing crackers, cream biscuits, and soda biscuits with consistent bite.

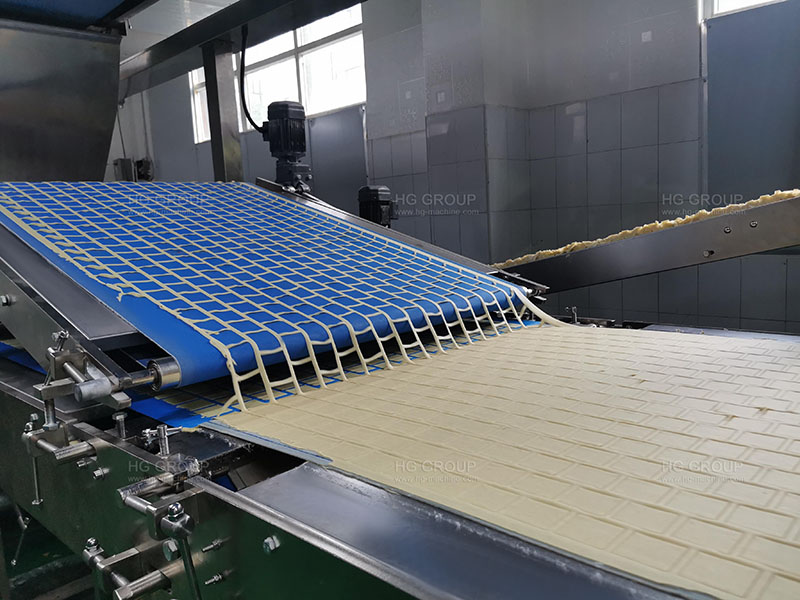

Sheeting, Gauging, and Cutting

A multi-stage sheeting and gauging system ensures precise thickness. Rotary cutters and docking units control shape and moisture release during baking.

High-Efficiency Baking

Long tunnel ovens with independent temperature zones gradually reduce moisture while maintaining structure. Accurate thermal control is key to achieving crispness without burning.

Comparison of Soft and Hard Biscuit Production Lines

| Item | Soft Biscuit Line | Hard Biscuit Line |

| Dough Moisture | High | Low |

| Forming Method | Wire-cut / Rotary mold | Sheeting & Rotary cutting |

| Baking Focus | Surface & softness | Crispness & structure |

| Typical Products | Cookies, soft biscuits | Crackers, cream biscuits |

Integrated Solutions from HG Industry Group

With over 50 years of experience in food machinery, HG Industry Group provides complete soft biscuit and hard biscuit production lines tailored to industrial-scale manufacturing. Founded in 1975, HG Food Machinery has grown into a global manufacturing network with seven machinery branches, two food laboratories, and a dedicated industrial university.

HG Industry integrates advanced R&D from Japan, intelligent manufacturing in Shanghai, and global service capabilities through MWM. This structure enables optimized line design, stable performance, and long-term production reliability.

Practical Advantages for Biscuit Manufacturers

- Customized line layouts based on product type, capacity, and factory space.

- Proven equipment exported to over 100 countries, ensuring global compliance and stability.

- One-stop supply covering raw materials, additives, equipment, and turnkey projects.

Choosing the Right Biscuit Production Line

Selecting between a soft biscuit production line and a hard biscuit production line depends on target products, output requirements, and long-term market positioning. Manufacturers benefit most from suppliers that combine engineering expertise, food technology knowledge, and global service experience.

HG Industry’s production lines are widely imitated but never surpassed, delivering consistent quality, scalable output, and sustainable performance for biscuit manufacturers worldwide.

English

English 中文简体

中文简体 日本語

日本語 русский

русский Español

Español Український

Український عربى

عربى Français

Français

Possessing more than 20 national patents

Possessing more than 20 national patents  4 pressure rollers, with a roller length of 420mm

4 pressure rollers, with a roller length of 420mm  Efficient dough sheet pressing

Efficient dough sheet pressing  Precise oil spraying and seasoning

Precise oil spraying and seasoning