Industry Knowledge

Bear Cake Production Line Overview

A bear cake production line is designed for automated manufacturing of shaped cakes with consistent appearance and stable texture. Developed in response to market demand for character-themed bakery products, this line supports continuous production of bear-shaped cakes with uniform size, color, and softness.

Shaped Cake Forming and Appearance Control

Bear cakes require accurate forming to maintain clear outlines and recognizable shapes. The production line uses dedicated depositing and forming systems combined with baking molds to achieve stable shaping throughout continuous operation.

- Precise batter depositing to ensure uniform cake volume

- Controlled baking to maintain surface definition and internal tenderness

- Stable demolding process to protect cake appearance

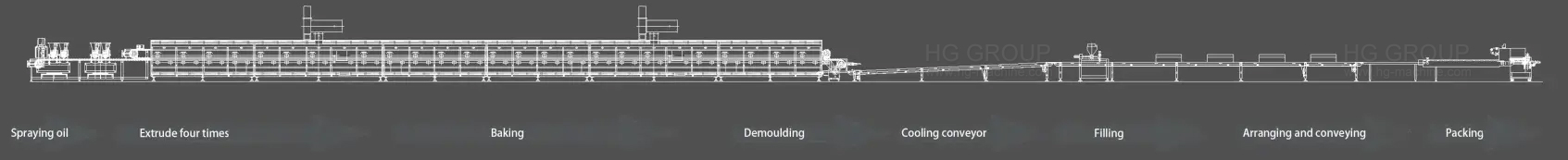

Fully Automatic Processing Flow

The bear cake production line integrates raw material feeding, oil spraying, depositing, baking, demolding, cooling, filling, and packing into a fully automatic workflow. Automated conveyors connect each stage, reducing manual handling and supporting continuous, stable production.

Product Applications and Market Demand

Bear cakes are widely used in packaged snack products, children-oriented bakery items, and themed food lines. Their attractive appearance and soft texture make them suitable for a broad consumer base, supporting strong demand in both domestic and overseas markets.

Equipment Manufacturing and Line Integration

HG Industry Group manufactures bear cake production lines with a focus on mechanical stability and automated coordination. Main equipment typically includes oil sprayers, extruders, baking ovens, demolding units, conveyors, filling machines, and packing systems.

With certified manufacturing standards and extensive experience in shaped cake equipment, HG Industry provides customized bear cake production line solutions aligned with different output capacities and product specifications.

English

English 中文简体

中文简体 日本語

日本語 русский

русский Español

Español Український

Український عربى

عربى Français

Français

Module Integration and Upgrade

Module Integration and Upgrade  Low-noise silent design

Low-noise silent design  Customized bear-shaped molds

Customized bear-shaped molds