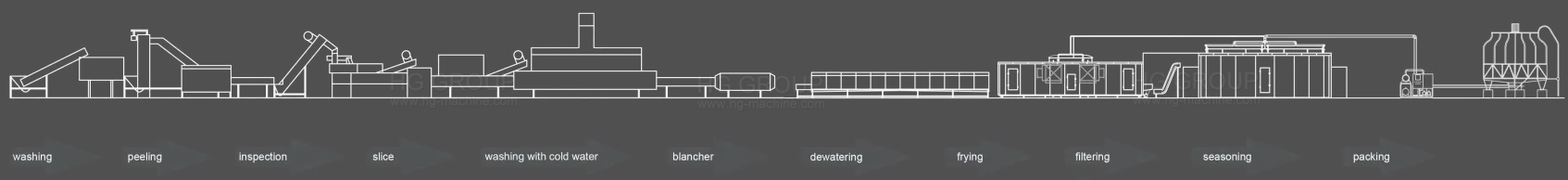

Natural Potato Chips Production Line

Contact UsProduction Line Details

Our potato chips production line uses fresh potatoes as material and can produce delicious potato chips through washing, peeling, cutting, oil frying, and flavoring. Our potato chips production line is very advanced; for instance, the blanching pool adopts a steam boiler to heat directly. After blanching, we use high pressure blower to dewater the potato chips,s and then oil fry them. After the process of oil frying, it will be deoiled and flavored.

The main equipment: Washing and destone machine、Peeling machine, Cutting Machine, Blancher, Fryer, and Seasoning machine.

Production Line Details

|

Capacity |

100 kg/h |

300 kg/h |

|

Power |

50 kw |

60 kw |

|

Gas consuming |

300 kg/h |

500 kg/h |

|

Length |

About 40m |

About 50m |

Advantages and Features

-

The manufacturer of China's largest output machines for natural potato chips

The manufacturer of China's largest output machines for natural potato chips -

Customized slicing solutions

Customized slicing solutions -

High-efficiency automated systems

High-efficiency automated systems

Machine Modeling Diagram

English

English