Industry Knowledge

Rice variety & milling targets (why “snow” texture starts here)

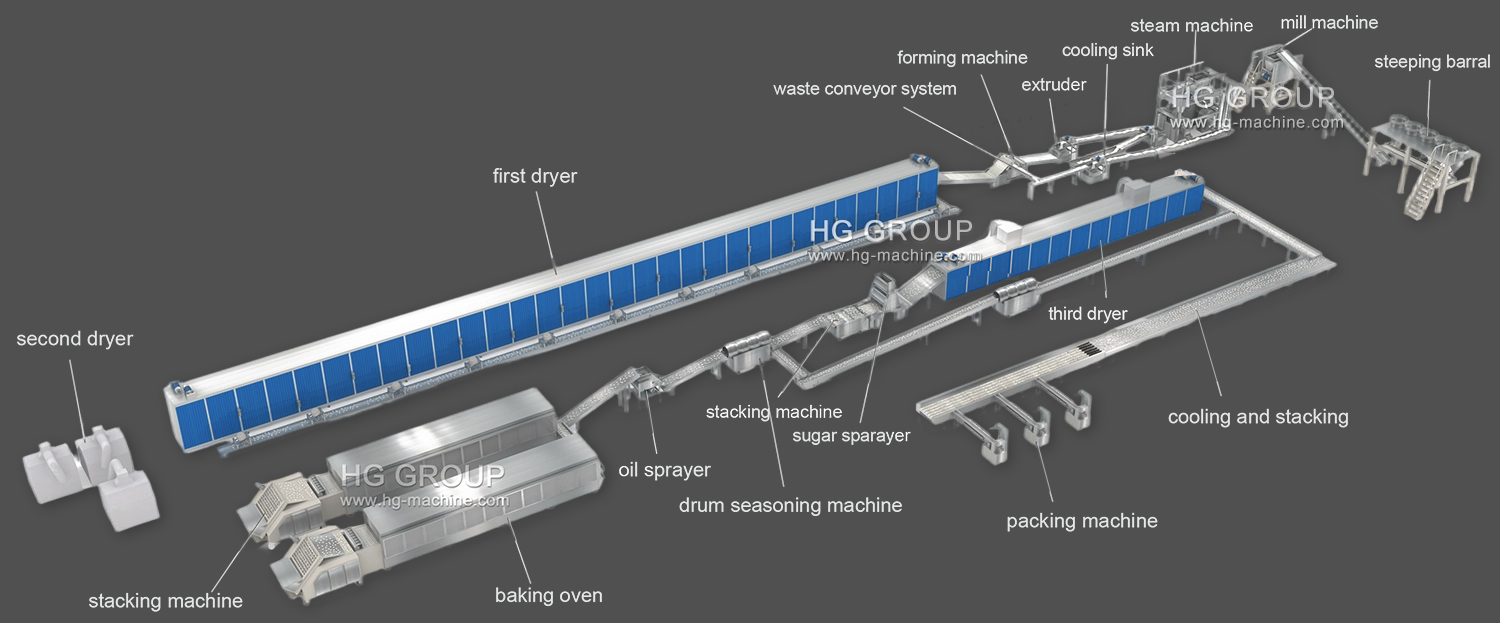

Snow-style crackers are unusually sensitive to rice starch behavior. Different Chinese rice varieties vary in amylose/amylopectin balance, which shifts puffing expansion, brittleness, and “snow” mouthfeel. A practical buying check is whether the line can tune milling fineness and moisture conditioning so the dough forms consistently without excessive fines or paste build-up. Our Japan/Taiwan-origin process logic is kept, but the key parameters are optimized around Chinese rice traits for stable large-batch output.

- Aim for a flour distribution that supports forming without tearing; overly coarse particles raise forming defects.

- Over-milling increases dust and sticking; look for dust control and easy-clean milling paths.

- Stable upstream milling reduces downstream scrap more than most buyers expect.

Forming stability: the hidden cost driver in high-output plants

In continuous production, forming is often where yield loss quietly accumulates: edge cracking, thickness drift, and shape distortion. The best indicator is not “max speed,” but whether forming holds tolerance over long runs as humidity and rice batch vary. We design for industrial consistency first—our goal is to keep your operator interventions low, not just to chase headline throughput.

- Ask how the line controls dough temperature and moisture before forming; those two variables dominate thickness stability.

- Check for quick-change tooling and repeatable alignment to reduce changeover waste.

- Forming repeatability is usually worth more than an extra 5–10% speed in total cost per ton.

Puffing control: how to prevent hollow centers, blistering, and “hard bite”

Snow rice cracker production line demand a narrow puffing window. Too aggressive and you get blistering or hollow centers; too mild and the bite becomes dense and hard. Buyers should evaluate how the line manages residence time, thermal profile, and product moisture at entry, because puffing amplifies any upstream inconsistency. A well-tuned puffing section is where you see the “snow” effect become repeatable across shifts.

- Look for multi-zone control or equivalent capability to shape expansion rather than “one temperature fits all.”

- Confirm the line can stabilize product moisture before puffing; moisture swings are the fastest path to uneven expansion.

- Consistent puffing starts with consistent feed condition—a line that integrates these controls will protect your margin.

Seasoning & oil management: keeping flavor uniform without sogginess

Seasoning is not only a flavor step; it is also a shelf-life and texture step. The same powder formula can taste different when adhesion changes, and excess oil can collapse the crisp “snow” texture over time. When comparing lines, focus on mixing uniformity, carryover loss, and how quickly the system can be cleaned when switching flavors. We keep the seasoning system practical for factory reality—fast cleaning and stable coating matter more than flashy features.

- Prefer adjustable dosing and controlled tumbling so you can run low-salt or high-spice SKUs without rework.

- Ask about powder recovery and dust extraction; seasoning loss can be a meaningful ongoing expense.

- Uniform coating is a consistency promise to your customers, not just a taste detail.

Packaging choices that protect crispness (and reduce returns)

For puffed rice products, packaging is part of the process. Moisture pickup and oxygen exposure degrade aroma and crunch, especially for seasoned variants. Buyers should align packaging format (pillow bag, nitrogen flush, multi-pack) with distribution distance and climate. In over-humid regions, packaging upgrades can outperform recipe tweaks in preventing “soft bite” complaints.

- Confirm seal integrity monitoring and stable film tension control for high-speed runs.

- If using nitrogen flushing, evaluate residual oxygen targets and validation method (not just “has flushing”).

- Packaging that preserves crispness protects brand reputation as much as it protects product.

Capacity planning: what “high output” really means in a full line

A snow rice cracker production line’s nameplate capacity is only useful if bottlenecks are balanced across milling, forming, puffing, seasoning, and packaging. In practice, packaging or seasoning often becomes the limiter. A constructive buyer approach is to request a throughput balance table and confirm buffer design between sections so micro-stops in packaging do not force repeated shutdowns upstream. With our 50-year manufacturing experience, we generally prioritize stable continuous operation over short-term peak figures—because your real KPI is weekly delivered tons.

Compliance & acceptance: what to prepare for smoother import/export projects

If your product will enter strict markets or you need third-party inspections, equipment documentation and certification readiness matter. We hold 300+ national patents and certifications, including CE, BV, and ISO, which can simplify buyer audits and project timelines. Practically, you should still confirm the scope: which modules, electrical standards, and safety devices are covered, and what inspection pack is provided.

- Ask for a documentation list: drawings, manuals, spare parts list, and validation records where applicable.

- Confirm safety interlocks and guarding match your site’s EHS requirements.

- Certification readiness reduces commissioning friction when deadlines are tight.

English

English 中文简体

中文简体 日本語

日本語 русский

русский Español

Español Український

Український عربى

عربى Français

Français

The first manufacturer of snow rice cake equipment in China

The first manufacturer of snow rice cake equipment in China  Automatic steam temperature control (solenoid valve temperature control)

Automatic steam temperature control (solenoid valve temperature control)  The new cake arranging machine with a high adsorption rate of 99%

The new cake arranging machine with a high adsorption rate of 99%