Industry Knowledge

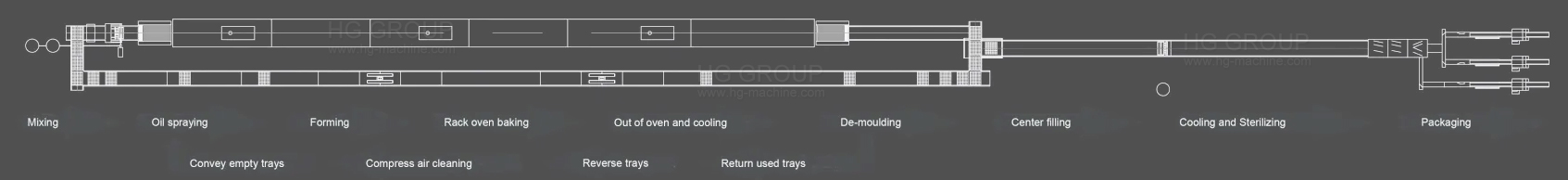

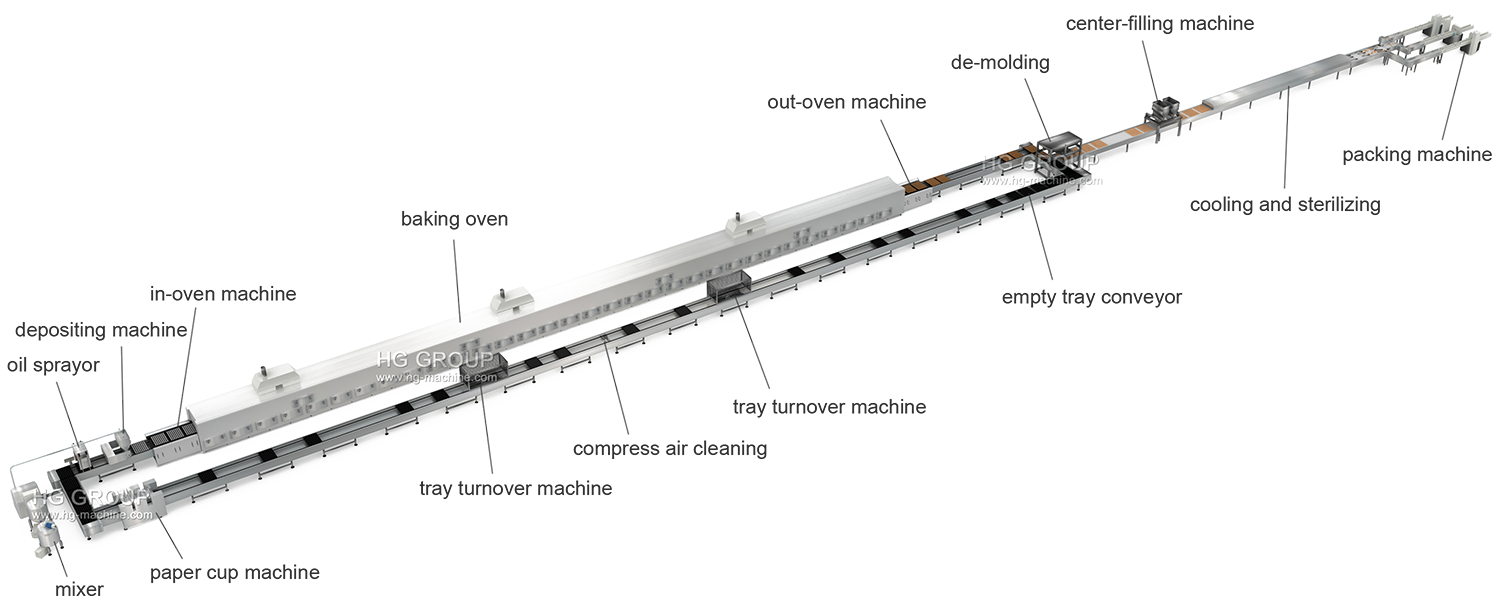

Muffin, Cup Cake, and Center Filled Cake Production Line Overview

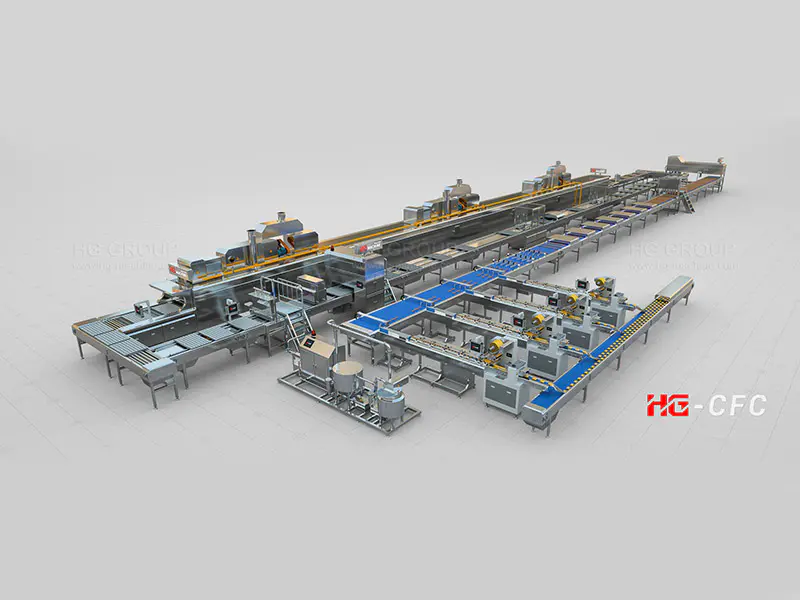

A Muffin Production Line is designed for automated production of small-format cakes with stable volume, texture, and appearance. By adjusting batter formulas, filling systems, and mold configurations, the same line can support muffins, standard cup cakes, and center filled cake products within a unified processing framework.

Product Flexibility and Mold-Based Forming

One key feature of modern cup cake production lines is their adaptability. Through interchangeable molds and depositing programs, manufacturers can produce cakes of different shapes and sizes while maintaining consistent weight and structure.

- Standard cup cakes produced with paper cups or metal trays

- Muffins made by adjusting batter composition, such as adding chocolate or fruit inclusions

- Center filled cakes using custard or cream injection systems

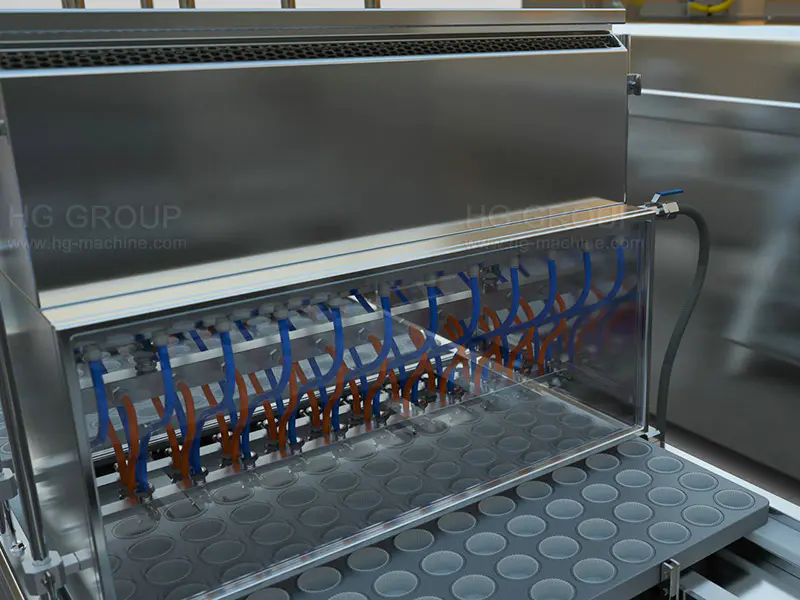

Center Filling Process Control

For center filled cake production lines, filling accuracy and timing are critical. Automated filling systems inject custard or cream either before or after baking, depending on product structure. Precise control helps maintain internal consistency without affecting cake shape or surface quality.

Hot Air Circulation Tunnel Oven Technology

The hot air circulation tunnel oven plays a central role in muffin and cup cake production. Developed based on imported equipment concepts, this oven adopts gas combustion combined with hot air circulation heating. Multiple temperature zones allow controlled baking across different stages, supporting uniform color development and soft internal texture.

Automatic temperature regulation through motorized control systems helps stabilize baking conditions during continuous operation, which is especially important for high-output cake lines.

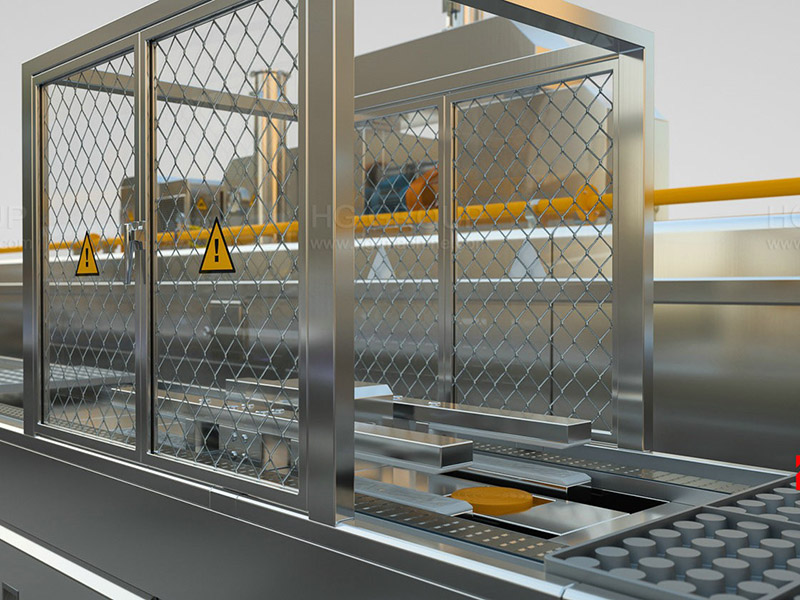

Equipment Manufacturing and Quality Standards

HG Industry Group manufactures muffin and cup cake production lines using food-grade stainless steel and selected electrical components from recognized domestic and international brands. Equipment design emphasizes durability, ease of operation, and compatibility with different production capacities.

Supported by certified manufacturing standards and a strong technical foundation, HG Industry provides customized cup cake and center filled cake production line solutions aligned with factory-scale and product positioning.

English

English

The weight error of each cake is within ±1g

The weight error of each cake is within ±1g  Free design of various styles of molds

Free design of various styles of molds  The most advanced and precise vertical core injection

The most advanced and precise vertical core injection  Hot air circulation tunnel oven with high output

Hot air circulation tunnel oven with high output