Swiss Roll/Layer Cake Production Line

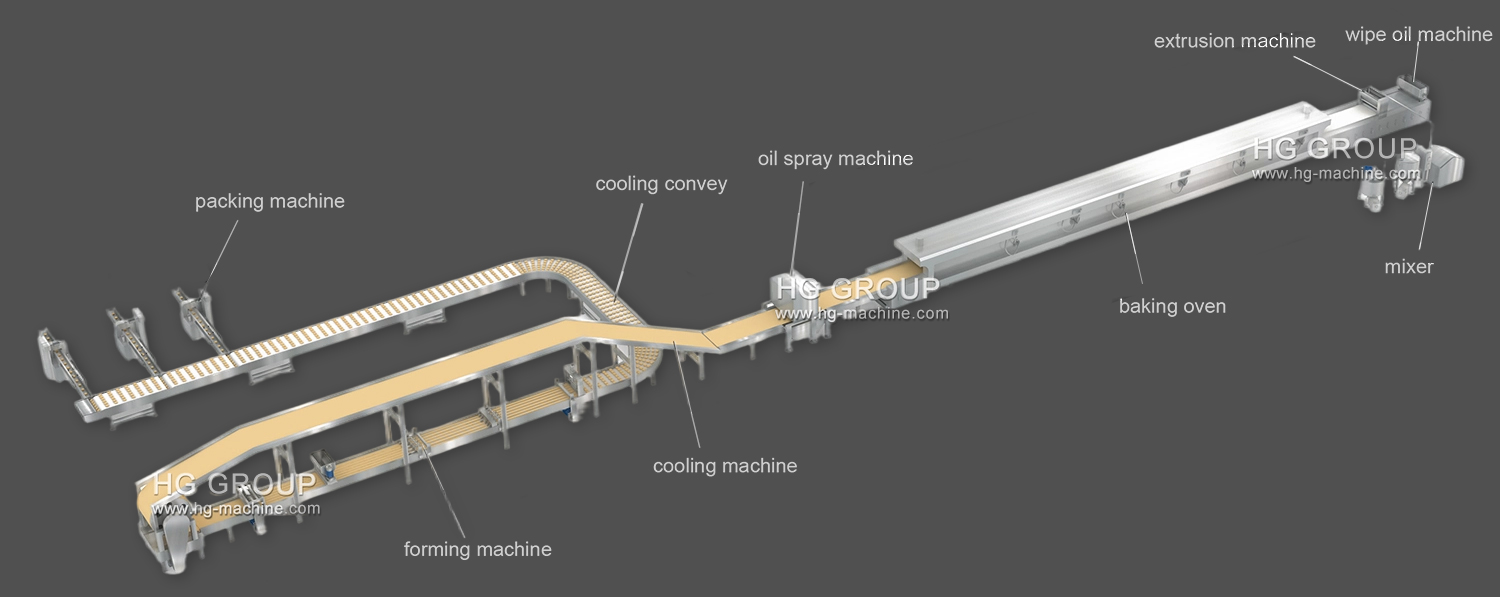

Contact UsThis whole set of equipment is researched and developed by our company to make Swiss roll & Layer cake. When producing this kind of cake, there is no need for molds, and we just need to change the cutter and adjust the speed of the horizontal cutter. The Swiss roll & Layer cake tastes soft and tender. Some characteristics of this Swiss roll/layer cake production line: The size, weight, and flavor of products can be changed, and it is also very convenient in production, easy in operation, and stable in running.

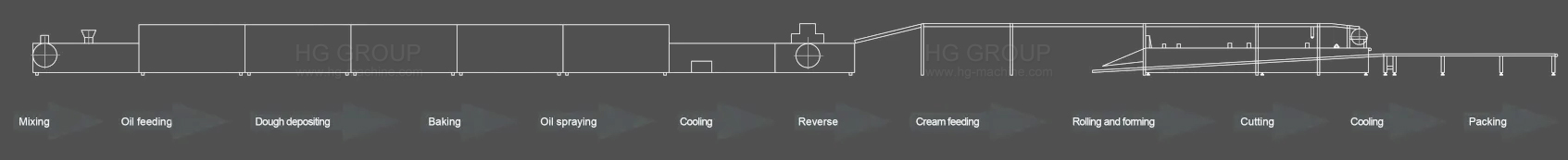

Working Principle: Firstly, deposit slurry on the steel belt to bake. Then, spray oil on the cakes and turn them over. Next, the machine will cut the cakes longitudinally and put cream on each line. Afterwards, turn over the line and press to the next line, and then cut the long cakes horizontally. In this process, you can decide how long the cake you want is. At last, you can get the Swiss roll or layer cake.

As Swiss Roll/Layer Cake Production Line Manufacturers and Swiss Roll/Layer Cake Production Line Factory in China, we hold 300+ national patents and certifications, including CE, BV, and ISO. With 50 years of expertise, HG Industry Group offer Custom Swiss Roll/Layer Cake Production Line, our products reach 100+ countries.

|

Production capacity |

6 T/day |

9 T/day |

|

Power |

28kw |

35kw |

|

Gas consuming |

28-30 m³/h |

30-35 m³/h |

|

Length of equipment |

68m(except pack) |

68m(except pack) |

|

Width |

800mm |

1000mm |

-

Microwave cutters are adopted to make the cakes smooth and neat

Microwave cutters are adopted to make the cakes smooth and neat -

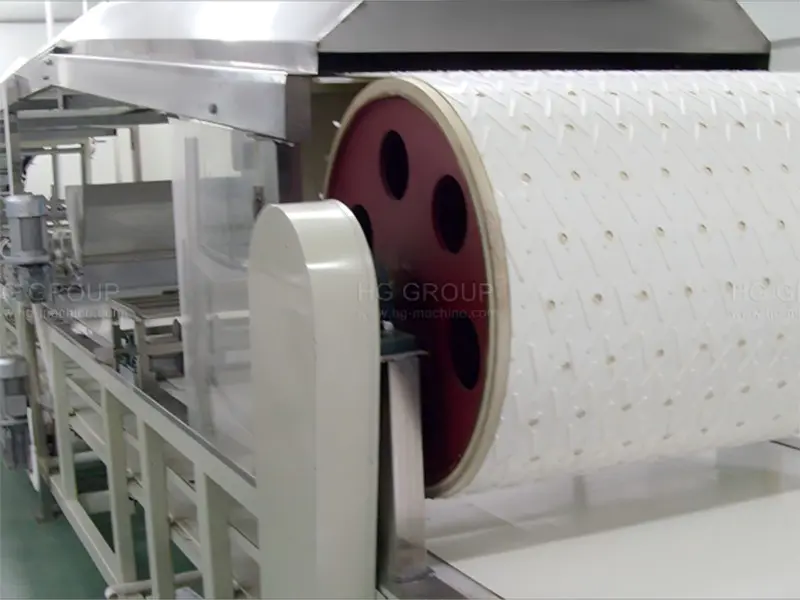

Dual-mode rolling / cutting system

Dual-mode rolling / cutting system -

The weight and length of the cake can be customized

The weight and length of the cake can be customized

English

English