Industry Knowledge

HG Industry Group's Baked Potato Chips Production Line: Innovation in Health-Conscious Snacks

HG Industry Group, with a legacy of 50 years in food machinery, has firmly established itself as an industry leader. Founded in 1975, its manufacturing arm, HG Food Machinery, is known for developing cutting-edge production equipment, including the highly efficient Baked Potato Chips Production Line. With a strong presence in over 100 countries and assets totaling RMB 2 billion, HG Food Machinery provides innovative solutions for snack manufacturers globally, helping them keep up with the growing demand for healthier snack alternatives.

The Baked Potato Chips Production Line by HG Food Machinery is specifically designed to cater to the rising consumer preference for healthier, low-fat snack options. Unlike traditional fried chips, baked potato chips retain a crisp texture and natural taste while offering a significantly lower fat content. This line is perfect for manufacturers looking to enter or expand in the health-conscious snack market.

Key Features of HG Baked Potato Chips Production Line

- Low-fat, healthier snack: The baked production method ensures that potato chips retain their crispness and flavor with minimal oil usage, making them a healthier alternative to fried chips.

- Energy-efficient baking technology: The production line incorporates advanced heating and baking technologies that reduce energy consumption, enhancing cost-efficiency without compromising on product quality.

- Uniform baking: The equipment is engineered to ensure even heat distribution, resulting in consistently baked chips with no burnt spots, ensuring optimal texture and color.

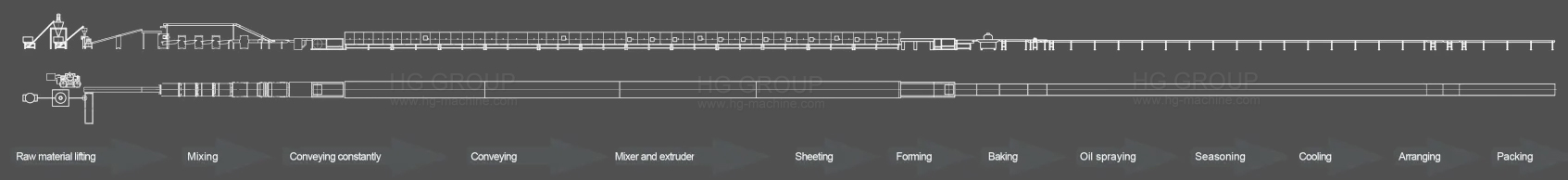

- Full automation: From washing and slicing to baking and packaging, the entire process is automated, reducing manual labor and improving production speed and consistency.

- Customizable for various flavors: The production line is adaptable to produce chips in a wide variety of flavors and seasoning options, offering flexibility for manufacturers to meet diverse consumer preferences.

Applications of Baked Potato Chips Production Line Equipment

The Baked Potato Chips Production Line by HG Food Machinery is an ideal solution for snack manufacturers focusing on creating healthier alternatives to traditional fried chips. The line is particularly suited for producing:

- Low-fat, baked potato chips

- Chips with organic or natural seasonings

- Gluten-free and allergen-free potato chips

- Chips with unique or premium flavors like rosemary, sea salt, or truffle

Efficiency and Quality in Baked Potato Chips Production

HG Food Machinery’s Baked Potato Chips Production Line not only delivers healthier snack options but also enhances overall production efficiency. With advanced technology that maximizes energy usage and reduces waste, the line ensures consistent, high-quality output while minimizing operational costs. The automated nature of the system reduces human error, which leads to more uniform batches and improved product quality.

By reducing the amount of oil used in the baking process, the production line ensures that chips retain their natural flavor and texture while maintaining lower fat content. This meets the growing demand for healthier snack options without compromising on taste, making it ideal for manufacturers seeking to capitalize on the health-conscious snack market.

Maintenance and Support for HG Baked Potato Chips Line

HG Food Machinery provides robust maintenance and support services to ensure that the Baked Potato Chips Production Line operates at optimal performance. These services include:

- Scheduled maintenance to avoid production delays and ensure continuous operation.

- On-demand access to replacement parts and spare components to minimize downtime.

- Operator training to ensure proper handling and maintenance of equipment.

- Remote technical support and on-site troubleshooting to resolve any production issues swiftly.

HG Industry Group's Commitment to Innovation in Snack Production

HG Industry Group’s commitment to innovation is demonstrated through its state-of-the-art Baked Potato Chips Production Line. With a strong focus on sustainability and product quality, HG Food Machinery continues to provide high-performance equipment that meets the ever-growing consumer demand for healthy snack alternatives.

HG’s global network of machinery branches, food labs, and research capabilities ensures that manufacturers can access localized support and cutting-edge solutions tailored to their specific needs. Whether you are looking to enter the health-focused snack market or expand your current offerings, HG Food Machinery provides the tools and expertise to help your business succeed.

With a proven track record of over five decades of experience, HG Food Machinery is the trusted partner for manufacturers aiming to produce high-quality, healthier snacks like baked potato chips while optimizing efficiency and production costs.

English

English 中文简体

中文简体 日本語

日本語 русский

русский Español

Español Український

Український عربى

عربى Français

Français

Fully automatic continuous production

Fully automatic continuous production  Full-process PLC automation

Full-process PLC automation  Food-grade 304/316L stainless steel material

Food-grade 304/316L stainless steel material