HG Industry Group's Expertise in Snack Production Line Equipment

HG Industry Group, a leading name in food machinery, brings over 50 years of experience in the industry. Established in 1975 as HG Food Machinery, the company has grown into a global player in food machinery with a wide range of offerings, including Snack Production Line and Baking Production Line Equipment. With assets exceeding RMB 2 billion and a vast global network spanning over 100 countries, HG Industry Group is known for its dedication to innovation, quality, and customer satisfaction.

The Snack Production Line by HG Food Machinery offers cutting-edge technology to meet the diverse needs of snack manufacturers worldwide. Whether you are producing chips, extruded snacks, or baked goods, HG's machinery ensures the highest standards of efficiency and product quality.

Key Features of HG Snack Production Line

- Advanced technology for diverse snack types: From extruded snacks to crispy chips, HG's production lines are adaptable for various snack products.

- Energy-efficient design: The production lines are engineered for maximum energy savings, reducing operational costs while maintaining high throughput.

- Modular system: Customizable configurations allow manufacturers to scale production based on demand and product variety.

- Comprehensive support: HG Food Machinery provides in-depth technical support and training to ensure seamless operations post-installation.

Applications of Snack Production Line Equipment

HG's Snack Production Line Equipment caters to a wide variety of snacks, offering precise control over the texture, taste, and appearance of the final product. Some of the most common applications include:

- Potato Chips Production

- Extruded Snacks (corn puffs, cheese snacks, etc.)

- Healthy Snacks (e.g., baked crackers, granola bars)

- Sweet Snacks (e.g., caramelized popcorn, chocolate-covered treats)

Baking Production Line Equipment by HG Industry Group

HG Industry Group's Baking Production Line Equipment is a prime example of the company's engineering excellence. Combining decades of experience with modern technology, HG delivers baking solutions that are fast, reliable, and scalable. The equipment is designed to meet the demands of the global food industry, ensuring top-quality baked products with consistency.

Benefits of HG's Baking Production Line

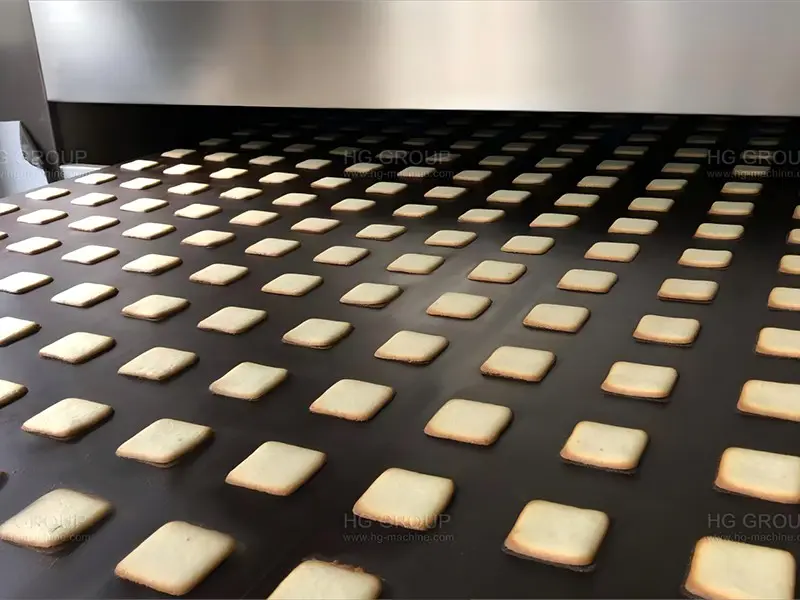

- Precision baking: The baking equipment allows for exact control of time and temperature, ensuring consistent product quality.

- Automatic systems: Automated feeding, baking, and cooling systems reduce manual labor, improving efficiency and reducing production costs.

- Versatility: The baking production lines can be customized to produce a variety of baked goods, from bread and cookies to pizza bases and pastries.

- Ease of cleaning and maintenance: Designed for convenience, HG's baking equipment features smooth surfaces and easy-to-remove parts for quick cleaning.

Common Applications of Baking Production Line Equipment

The Baking Production Line Equipment offered by HG is widely used for manufacturing a variety of baked products. Some of the most common applications include:

- Industrial Bread Production

- Cookie and Biscuit Manufacturing

- Pizza Crust Production

- Pastry and Croissant Production

Optimizing Your Production with HG's Baking and Snack Production Lines

HG Industry Group’s expertise extends far beyond just manufacturing equipment. With 50 years of research and development in food machinery, they provide customers with tailored solutions to optimize production processes. The integration of advanced technologies, including automation and energy-saving features, sets HG apart from other manufacturers in the industry.

In addition to offering high-quality machinery, HG Food Machinery provides in-depth consultations to help clients choose the best production line configuration for their specific needs. This ensures maximum efficiency, scalability, and product quality.

Comprehensive Support Services

- Installation and Setup: HG’s team of engineers oversees the entire installation process to ensure proper functioning.

- Training Programs: Comprehensive training programs are available for operators and maintenance staff to ensure smooth operations.

- Ongoing Maintenance Support: HG offers a range of post-installation services to keep the equipment in top condition.

- Upgrades and Customization: As technology evolves, HG provides solutions for upgrading and customizing your production lines.

With its extensive experience and global reach, HG Industry Group is a trusted partner in the food machinery industry, offering innovative solutions that boost productivity and quality for snack and baked goods manufacturers worldwide.

English

English Cake Production Line

Cake Production Line

Rice Cracker Production Line

Rice Cracker Production Line

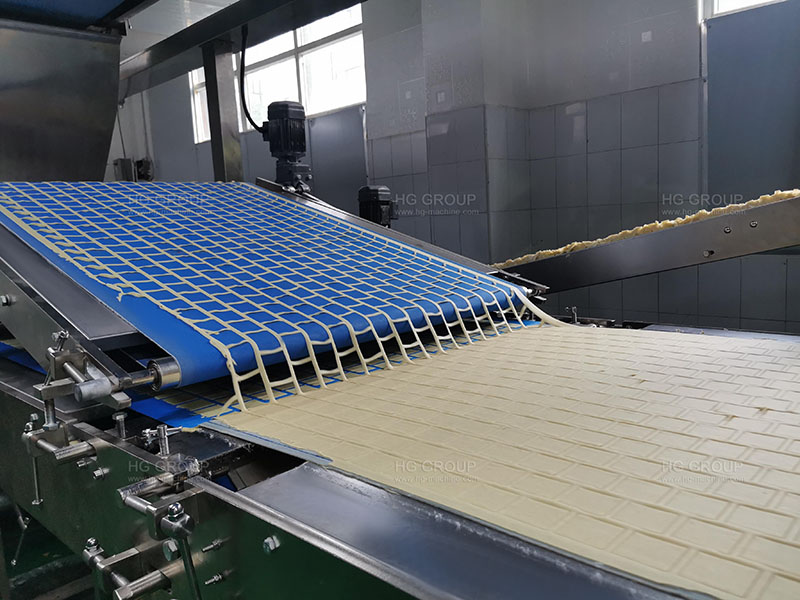

Biscuit Production Line

Biscuit Production Line

Cookie Production Line

Cookie Production Line

Wafer Production Line

Wafer Production Line

Pastry Production Line

Pastry Production Line

Other Food Production Line

Other Food Production Line

Module Integration and Upgrade

Module Integration and Upgrade  Low-noise silent design

Low-noise silent design  Customized bear-shaped molds

Customized bear-shaped molds

Customizable in various shapes

Customizable in various shapes  304 stainless steel

304 stainless steel  Possessing more than 20 national patents

Possessing more than 20 national patents

The first manufacturer of snow rice cake equipment in China

The first manufacturer of snow rice cake equipment in China  Automatic steam temperature control (solenoid valve temperature control)

Automatic steam temperature control (solenoid valve temperature control)  The new cake arranging machine with a high adsorption rate of 99%

The new cake arranging machine with a high adsorption rate of 99%

4 pressure rollers, with a roller length of 420mm

4 pressure rollers, with a roller length of 420mm  Efficient dough sheet pressing

Efficient dough sheet pressing  Precise oil spraying and seasoning

Precise oil spraying and seasoning

PLC control

PLC control  Automatic stacking function

Automatic stacking function  Data management

Data management

Precise control of chocolate tempering

Precise control of chocolate tempering  Accurate fitting of cat's tongue biscuits

Accurate fitting of cat's tongue biscuits  Rapid cooling and setting

Rapid cooling and setting