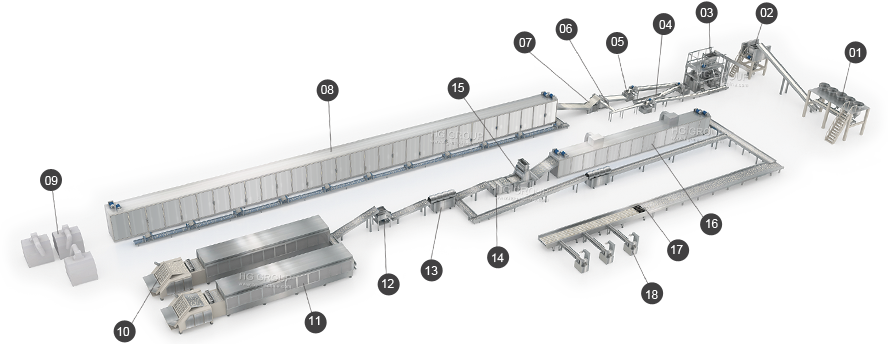

Some tips on how to maintain a Full-Automatic Rice Cracker Production Line

Regular cleaning: Rice cracker production lines require regular cleaning to prevent contamination and ensure the quality of the end product. Make sure to clean all equipment, including conveyor belts, rollers, and cutting blades, to avoid cross-contamination of different ingredients.

Lubrication: The moving parts of your production line need to be well lubricated to prevent wear and tear, minimize downtime, and extend the life of your equipment. Be sure to follow the manufacturer's recommendations for lubrication.

Regular inspections: Schedule regular inspections of your production line to identify any wear and tear, loose connections, or other issues that may impact production. Fixing problems early can prevent downtime and save you money in the long run.

Proper calibration: Calibration of your equipment is critical for maintaining consistent product quality. Make sure to calibrate your equipment regularly, following the manufacturer's recommendations.

Staff training: Train your staff to operate and maintain the production line properly. Make sure they understand the importance of cleanliness, lubrication, inspection, and calibration, and empower them to identify and report any issues.

Record-keeping: Keep detailed records of maintenance, cleaning, and calibration activities. This can help you identify trends and patterns, make informed decisions about when to replace equipment, and provide evidence of compliance in the event of an audit.

By following these tips, you can help ensure that your full-automatic rice cracker production line runs smoothly, producing high-quality products while minimizing downtime and maintenance costs.

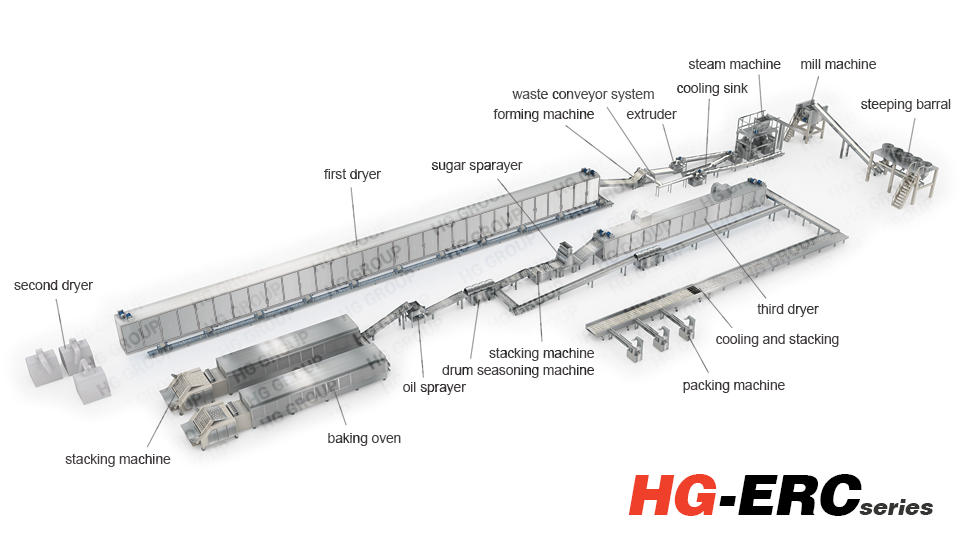

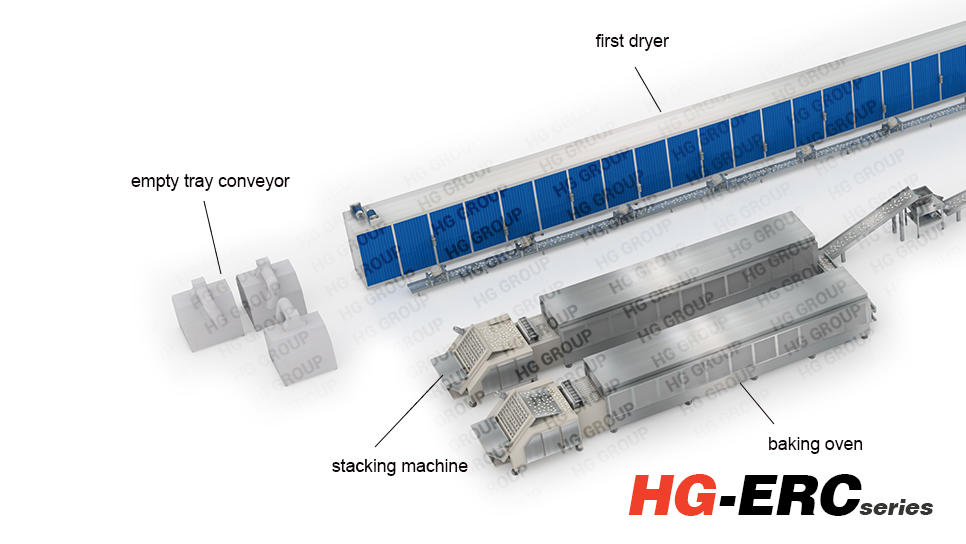

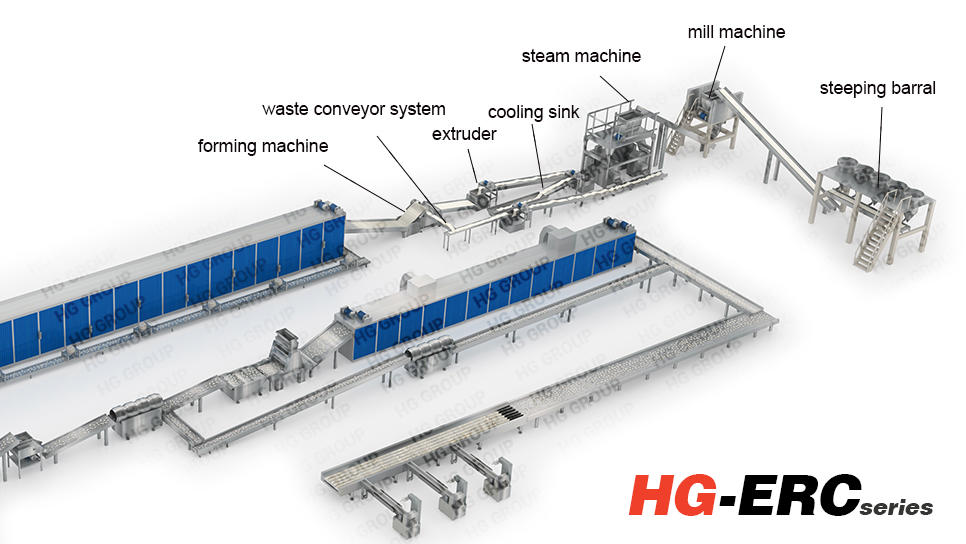

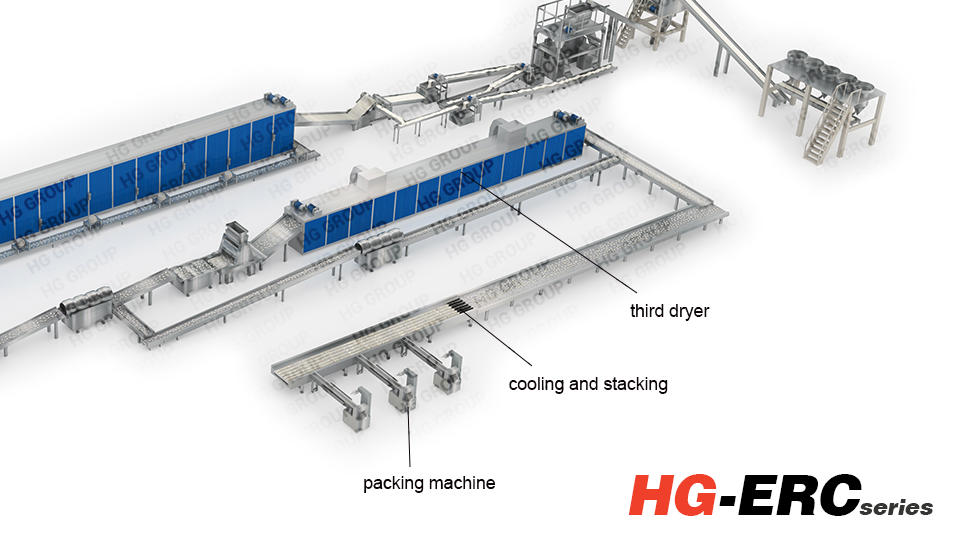

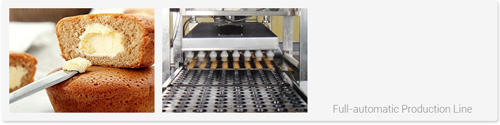

Use of Rice Cracker Machine

A rice cracker machine is a piece of equipment that is specifically designed to produce rice crackers on a large scale. Here are some steps on how to use a rice cracker machine:

Prepare the ingredients: The ingredients for making rice crackers typically include rice flour, water, and seasonings. Measure out the ingredients according to the recipe.

Preheat the machine: Turn on the

rice cracker machine and let it preheat to the desired temperature. Follow the manufacturer's instructions for preheating.

Mix the ingredients: Mix the rice flour, water, and seasonings in a large mixing bowl. Use a whisk or a mixer to ensure that the ingredients are well combined.

Fill the hopper: Fill the hopper of the rice cracker machine with the mixed ingredients. The hopper is the top part of the machine that holds the mixture.

Adjust the settings: Adjust the settings on the rice cracker machine according to the desired thickness and shape of the crackers. Follow the manufacturer's instructions for adjusting the settings.

Start the machine: Start the rice cracker machine and let it run until the crackers are formed. The machine will automatically cut the crackers to the desired length and shape.

Collect the crackers: As the crackers come out of the machine, collect them in a container or on a conveyor belt. Let the crackers cool before packaging them.

Clean the machine: After using the

food machine, clean it thoroughly according to the manufacturer's instructions. This will help ensure that the machine remains in good condition and produces high-quality crackers in the future.

By following these steps, you can use a rice cracker machine to produce high-quality rice crackers on a large scale.