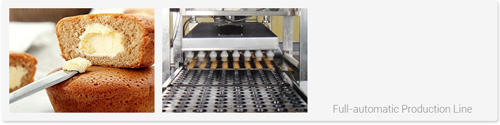

Knowledge of Full automatic Soft/Hard Biscuit Production Line

A

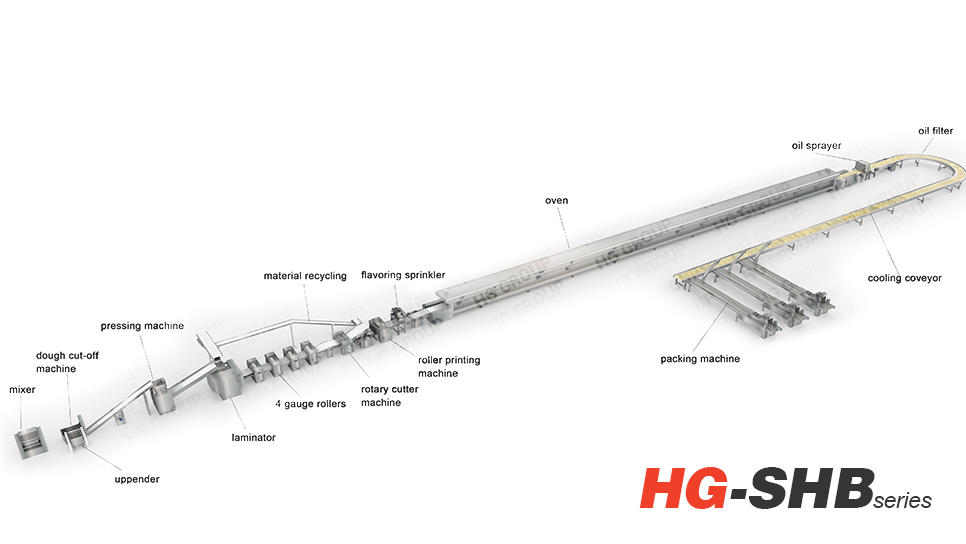

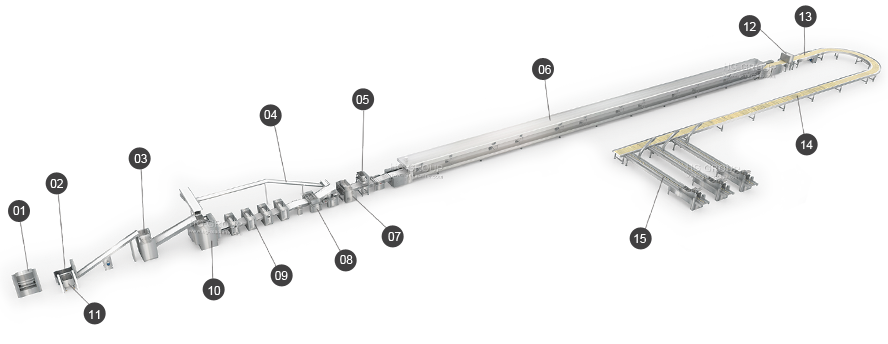

full automatic soft/hard biscuit production line is a complete system for making biscuits in large quantities. It typically includes several stages, each with specific machinery and equipment for different tasks. Here are some of the key components of a typical full automatic soft/hard biscuit production line:

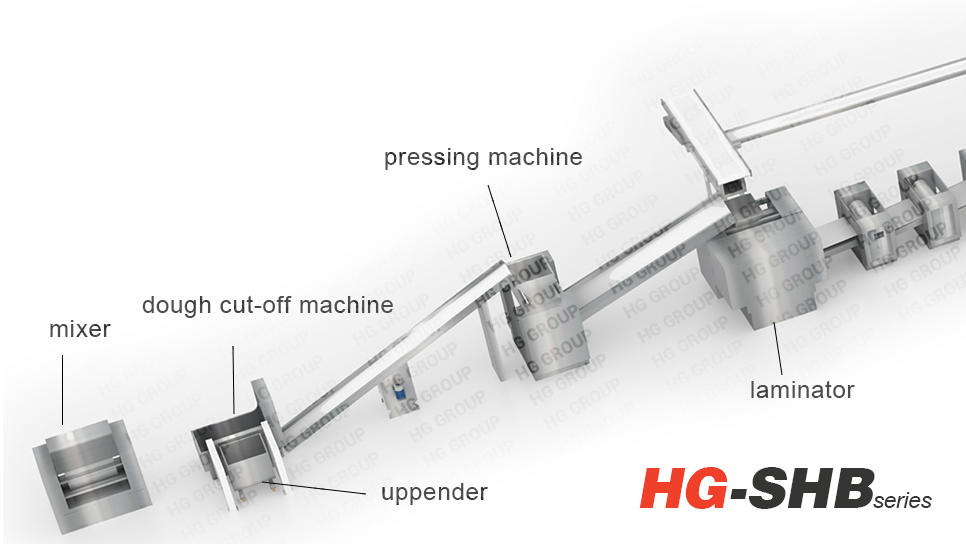

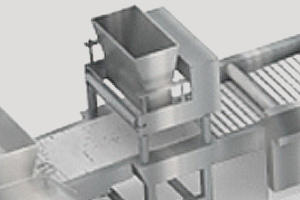

Mixing: This is the first stage of the process where the ingredients are mixed together in a large mixing tank. The ingredients typically include flour, sugar, fat, leavening agents, and other additives. The mixing process ensures that all the ingredients are thoroughly combined.

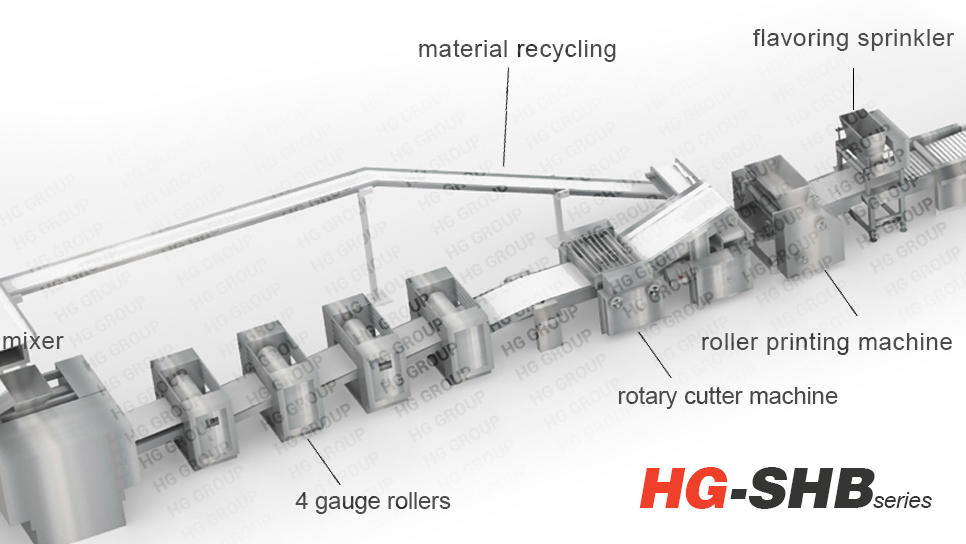

Forming: Once the dough is mixed, it is passed through a series of rollers and cutters to form the biscuits into the desired shapes and sizes. This stage can be done manually or with automated machinery.

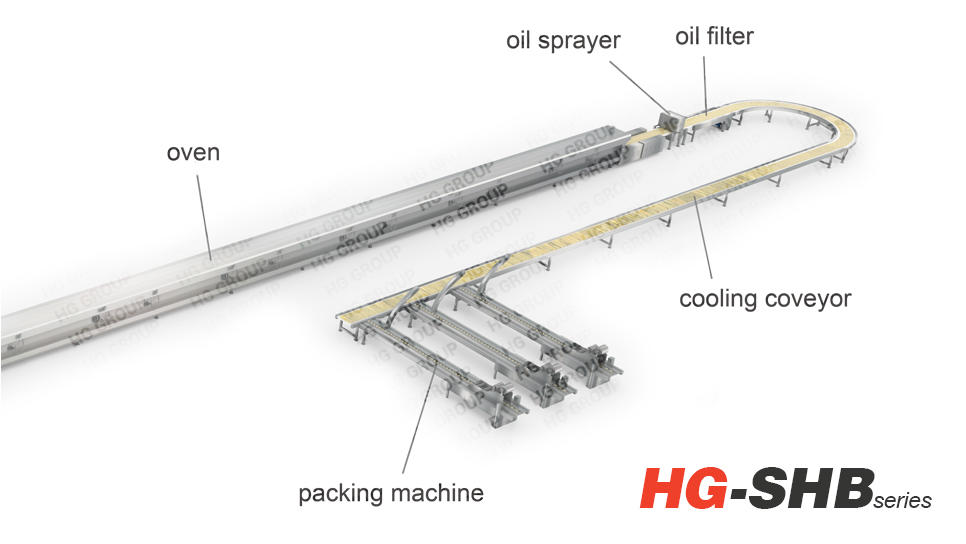

Baking: After the biscuits are formed, they are baked in large ovens at high temperatures. The baking process ensures that the biscuits are cooked evenly and develop the desired texture and flavor.

Cooling: After the biscuits are baked, they are cooled on a conveyor belt to prevent them from becoming too brittle.

Packaging: Finally, the biscuits are packaged into boxes or bags using automated packaging machinery.

A full automatic soft/hard biscuit production line typically includes all of these stages and can produce large quantities of biscuits in a short amount of time. The machinery used in the process can be customized to meet specific production needs and requirements.

Daily cleaning of Biscuit Making Machine

Cleaning your biscuit making machine regularly is important to maintain hygiene, prevent contamination and ensure efficient operation. Here are some general tips for daily cleaning of a

biscuit making machine:

Turn off and unplug the machine before cleaning.

Remove any leftover dough or biscuit crumbs from the machine using a soft brush or cloth.

Use warm soapy water to clean the machine, paying particular attention to any areas that come into direct contact with the dough or biscuits.

Rinse the machine thoroughly with clean water, making sure to remove all traces of soap.

Dry the machine with a clean, dry cloth or allow it to air dry.

Once the

food machine is completely dry, you can use a food-grade lubricant to lubricate the moving parts.

Finally, ensure that all the machine components are correctly reassembled and the machine is ready for use.

Remember, it's essential to follow the manufacturer's instructions when cleaning your biscuit making machine, as different models may require specific cleaning procedures or products.