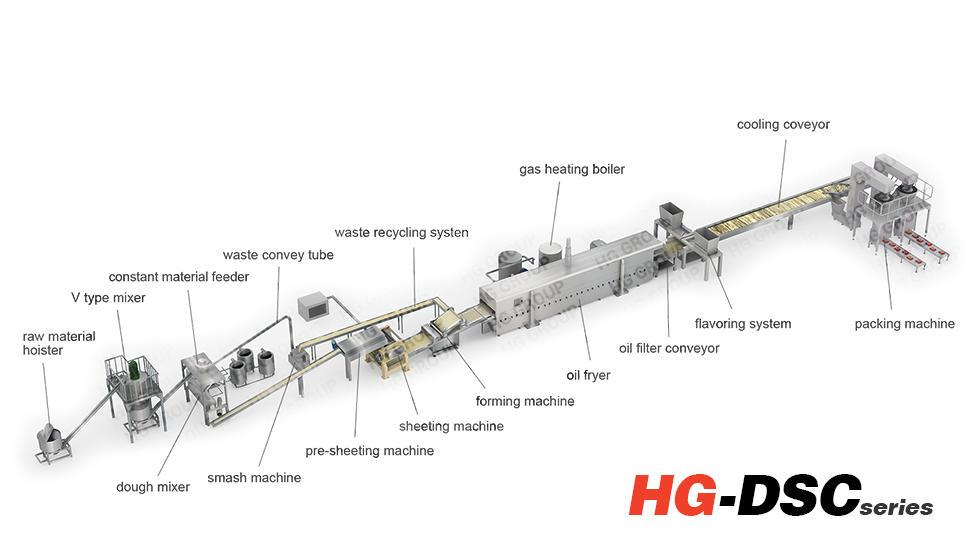

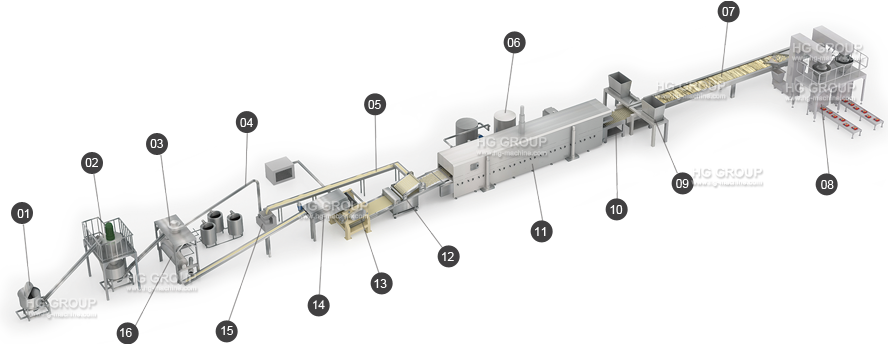

Functions of Full-automatic Potato Chips Machine

A

full-automatic potato chips machine is a piece of industrial equipment designed to automate the process of producing potato chips, from washing and slicing the potatoes to frying and seasoning the chips. Some of the functions of a full-automatic potato chips machine include:

Potato washing and peeling: The machine comes with a built-in washer and peeler, which removes the dirt and skin from the potatoes.

Potato slicing: The

food machine has a slicer that cuts the potatoes into thin, uniform slices.

Blanching: The potato slices are blanched in hot water to remove excess starch and prepare them for frying.

Frying: The potato slices are fried in oil at high temperatures until they are crispy and golden brown.

De-oiling: The excess oil is removed from the potato chips using a centrifugal system.

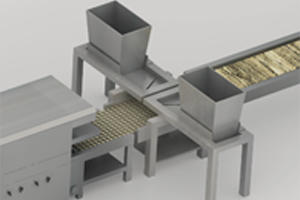

Seasoning: The potato chips can be seasoned with a variety of flavors, such as salt, cheese, BBQ, and vinegar.

Packaging: The machine can package the potato chips into bags or containers, ready for distribution.

By automating these processes, a full-automatic potato chips machine can significantly increase production efficiency and reduce labor costs for manufacturers.

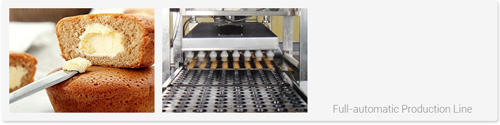

Features of Full-automatic Compound Potato Chips Production Line

A full-automatic compound potato chips production line is an advanced piece of equipment that is designed to streamline the process of producing high-quality potato chips. Here are some of the key features of a

full-automatic compound potato chips production line:

Fully automated: The production line is fully automated, which means that it can perform all of the steps in the potato chip production process with minimal human intervention.

High efficiency: The production line is designed to operate at high speeds, which means that it can produce a large quantity of potato chips in a short amount of time.

High yield: The production line is designed to minimize waste, which means that it can produce a high yield of potato chips from each batch of potatoes.

Consistent quality: The production line is designed to ensure consistent quality in the potato chips, with uniform thickness, crispiness, and flavor.

Multiple functions: The production line can perform multiple functions, such as washing, peeling, slicing, blanching, frying, seasoning, and packaging, all in one continuous process.

Energy-efficient: The production line is designed to be energy-efficient, with advanced heating and cooling systems that reduce energy consumption.

Easy to operate: The production line is designed to be user-friendly, with simple controls and easy-to-follow instructions.

Overall, a full-automatic compound potato chips production line is an advanced piece of equipment that can significantly improve the efficiency, yield, and quality of potato chip production.

Knowledge of Potato Chips Line

A

potato chips line, also known as a potato chips production line or potato chips processing line, is a series of interconnected machines and equipment that are used to produce potato chips on an industrial scale. Here are some key areas of knowledge related to potato chips lines:

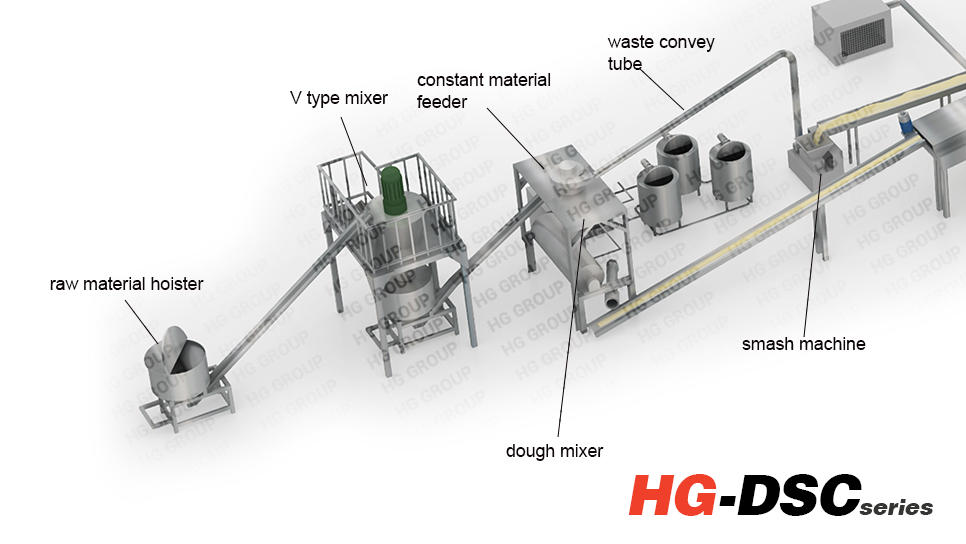

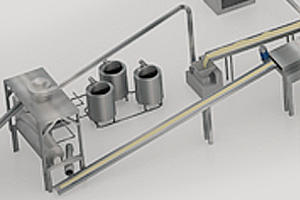

Raw material preparation: The production line begins with the preparation of the raw materials, which typically involves washing and peeling the potatoes to remove any dirt and skin.

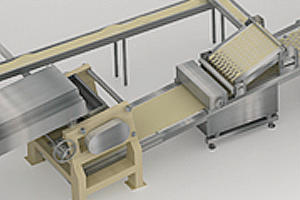

Slicing: The potatoes are then sliced into thin, uniform pieces using a potato slicer or cutter. The thickness of the potato slices can be adjusted to produce different types of potato chips.

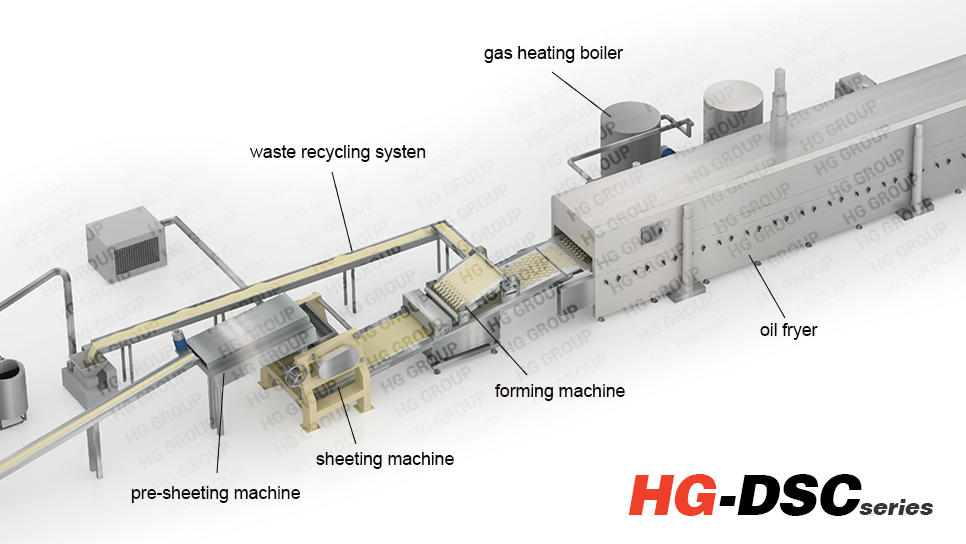

Blanching: The potato slices are blanched in hot water or steam for a short period of time to remove excess starch and prepare them for frying.

Frying: The potato slices are then fried in oil at high temperatures until they are crispy and golden brown. The frying process typically takes place in a continuous fryer, which can fry large quantities of potato chips at once.

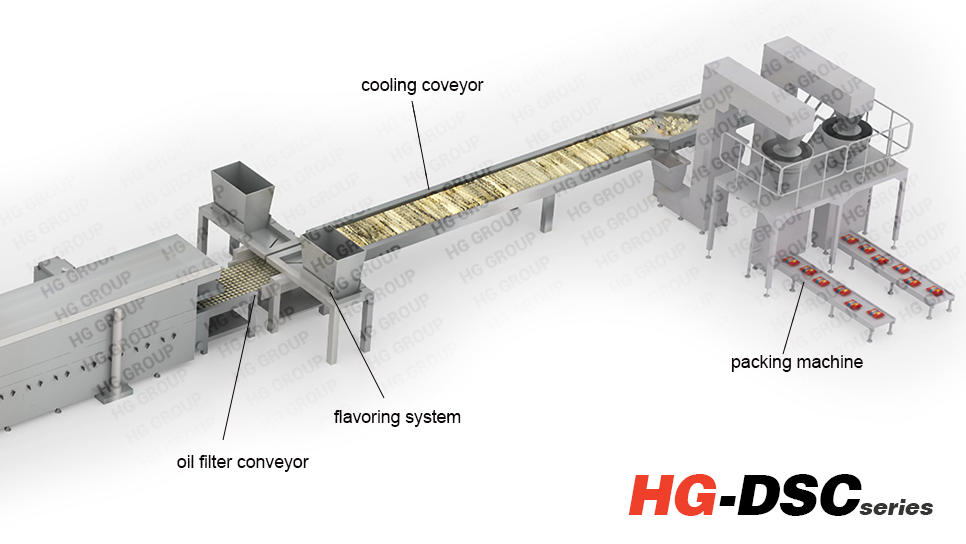

De-oiling: The excess oil is removed from the potato chips using a centrifugal system, which spins the chips to remove the oil.

Seasoning: The potato chips can be seasoned with a variety of flavors, such as salt, cheese, BBQ, and vinegar. The seasoning can be applied either during or after the frying process.

Packaging: The potato chips are then packaged into bags or containers, ready for distribution.

Quality control: Throughout the production process, quality control measures are in place to ensure that the potato chips meet certain standards for taste, texture, and appearance.

Maintenance: Regular maintenance and cleaning of the equipment is necessary to ensure the production line operates efficiently and safely.

Overall, a potato chips line is a complex system that requires specialized knowledge and skills to operate and maintain. A full understanding of the various processes involved in potato chip production is essential for anyone working in this field.