Daily maintenance of JAFFA Cake Line

Cleanliness: The production line should be thoroughly cleaned at the end of each shift to ensure that it is free from any contaminants or debris. This includes the equipment, floors, walls, and ceilings.

Inspection: Regular inspection of equipment, such as mixers, ovens, conveyors, and packaging

food machine, should be done to check for any signs of wear and tear or damage. Any issues should be addressed immediately to avoid production downtime.

Lubrication: All moving parts should be lubricated regularly to prevent them from rusting or sticking.

Calibration: The production line should be calibrated regularly to ensure that all machines are operating within the correct parameters.

Record Keeping: Maintain accurate records of maintenance tasks, including cleaning schedules, repairs, and replacement parts to ensure that the production line is functioning optimally.

Training: Provide regular training to staff members to ensure that they are following proper maintenance procedures and are equipped to identify and report any issues that arise.

By following these guidelines, the

JAFFA Cake production line can be kept in good condition, ensuring high-quality products and minimizing the risk of downtime or product recalls.

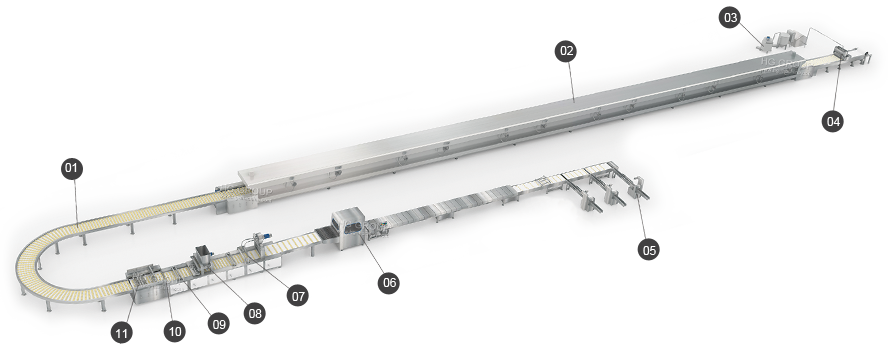

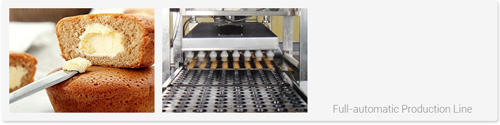

Introduction to Full Automatic Sandwich Cake Production Line

A

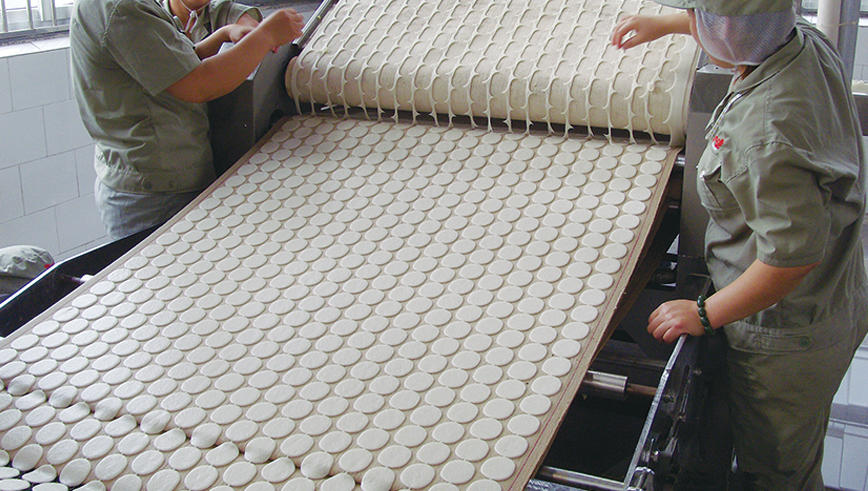

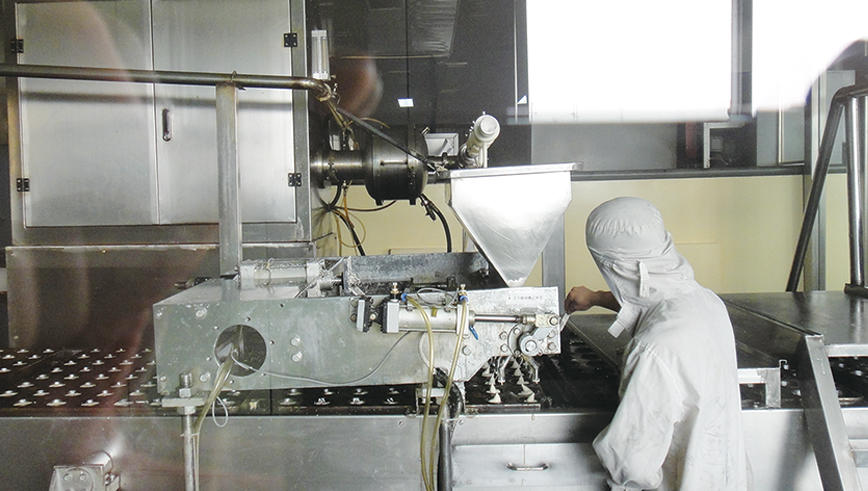

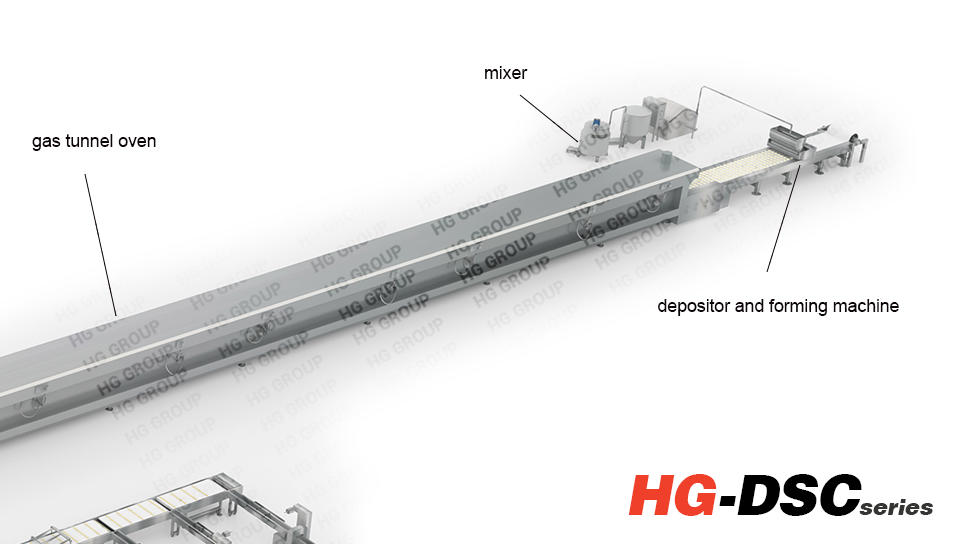

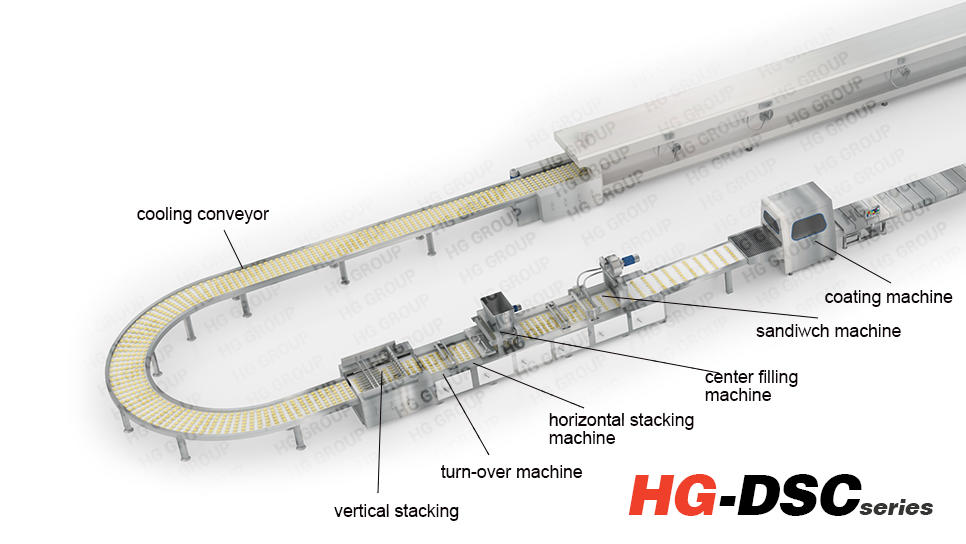

Full Automatic Sandwich Cake Production Line is a system that is designed to produce a variety of sandwich cakes with high efficiency and consistency. The production line consists of various machines that work together seamlessly to produce the final product.

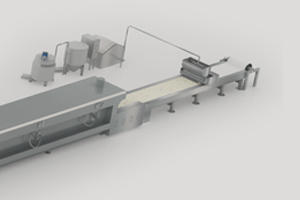

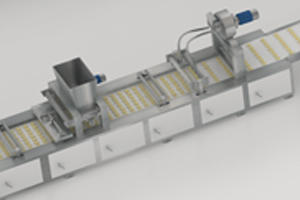

The production line usually includes equipment such as mixing machines, filling machines, baking ovens, cooling conveyors, and packaging machines. The mixing machines are used to prepare the cake batter, and the filling machines are used to add cream, jam, or other fillings to the cakes. The baking ovens are used to bake the cakes, and the cooling conveyors are used to cool them down before they are packaged.

The production line is fully automated, which means that it can operate without the need for manual intervention. This results in a more efficient and cost-effective production process, as well as higher quality and consistency of the final product. Additionally, the automatic production line can operate continuously, allowing for a higher production capacity.

Full Automatic Sandwich Cake Production Lines are commonly used by large-scale bakeries and confectionery manufacturers to produce a high volume of sandwich cakes quickly and efficiently. The production line can be customized to meet specific production requirements, including the size, shape, and filling of the cakes. Overall, the Full Automatic Sandwich Cake Production Line is a reliable and effective solution for producing high-quality sandwich cakes at a large scale.